KenTIP FS Modular Drill

KenTIP FS Modular Drill

Some good ideas can be made even better. Much better. This was certainly the case when Kennametal engineers took the strength and versatility of their proven KSEM modular drill system and combined it with the ease of use and low feed forces of its smaller companion drill, KenTIP, the company reports. The resulting fusion of these advanced holemaking technologies is the KenTIP FS, a 6 mm to 26 mm, 1.5 to 12 x D modular drill that's simple to use, produces good hole quality, and is tough enough to compete with solid-carbide drills across a wide range of materials.

Some good ideas can be made even better. Much better. This was certainly the case when Kennametal engineers took the strength and versatility of their proven KSEM modular drill system and combined it with the ease of use and low feed forces of its smaller companion drill, KenTIP, the company reports. The resulting fusion of these advanced holemaking technologies is the KenTIP FS, a 6 mm to 26 mm, 1.5 to 12 x D modular drill that's simple to use, produces good hole quality, and is tough enough to compete with solid-carbide drills across a wide range of materials.

Why KenTIP FS? Alexander Schmitt, senior global product manager for modular drilling at Kennametal, says FS denotes the tool's "full solid" carbide tip. It just looks like the tip of a solid-carbide drill. That means the carbide tip fully covers and protects the steel holder from washing out, but he adds that the meaning goes a bit further. "The KenTIP FS not only looks like a solid-carbide drill; it also works like one. So you can think of it as a fusion of solid-carbide's best characteristics together with the cost-effectiveness of indexable drilling tools."

At first glance, the KenTIP FS appears to be like any other replaceable tip drill, with a disposable carbide insert, coolant through the tool, and a helical flute for efficient chip removal. The similarities end there, however. The KenTIP FS has a new design, one that incorporates a number of important features that separate it from the "me too" modular drilling crowd, according to the company.

For starters, the flutes are smooth and shiny. That's because they're highly polished after final machining, a process that Kennametal has found greatly improves chip evacuation and reduces wash out near the tip. And instead of the two coolant holes found in most modular drill designs, the KenTIP FS has four: two at the tip and two in the chip

gullet directly behind the head. This "multicoolant" approach provides greater coolant volume to prevent chip packing while simultaneously drawing heat away from the cutting zone, prolonging tool life and improving hole quality.

"Multicoolant allows us to tailor the cutting fluid needs to the application," Schmitt explains. "For example, adhesion and flank wear are a big concern in stainless steels and cast irons. Inserts with HPL- and HPC-point styles have through-the-tool coolant channels to provide better lubrication in this area to overcome the issue. In steel though, it's better to concentrate coolant to the rake and take the heat from the contact zone between chip and rake surface. So we eliminated the front coolant holes in our HPG geometry inserts to raise our insert tool life and improve chip breakage. In addition, this avoids built-up edge and makes the insert more rigid, which allows higher penetration rates in steel applications."

There's more to application tuning than the number of coolant holes an insert has. The HPG geometry is available in a new, highly wear resistant carbide grade, KCP15A, designed especially for steel. Its newly-designed point angle and self-piloting chisel edge offers better positioning accuracy and hole straightness than other drills in this class, even under high feed rates. The insert corners are protected with small chamfers to reduce chipping, and the margins are similarly reinforced, making the HPG geometry suitable for the cross holes and inclined exits encountered in hydraulics manifolds, for example, or the stacked plates used in heat exchanger production.

If the world drilled only steel, HPG geometry inserts might be sufficient, but the aerospace industry needs stainless steels and superalloys, while automotive manufacturers make extensive use of cast iron. For the former, Kennametal offers the HPL geometry, which has a split-point designed to reduce cutting forces and break up long-chipping aerospace and medical alloys. Like the HPG geometry, it too is available in a new grade, in this case KCMS15, a wear-resistant, fine-grain carbide with an anti-adhesive AlTiN coating that extends tool life. And for cast, ductile, and compacted graphite irons, the HPC geometry offers four margin lands and a radiused point that eliminates the exit chipping and cracking common with these materials, with a specially-designed chip gash that clears chips quickly in combination with the front coolant exits.

All three insert styles have 143-degree points, and specially prepared, polished or honed edges for

maximum tool life. "Between the HPG, HPC and HPL geometries, the KenTIP FS can handle most anything a solid-carbide drill can, but with far lower cost per part and equal or greater performance," says Schmitt.

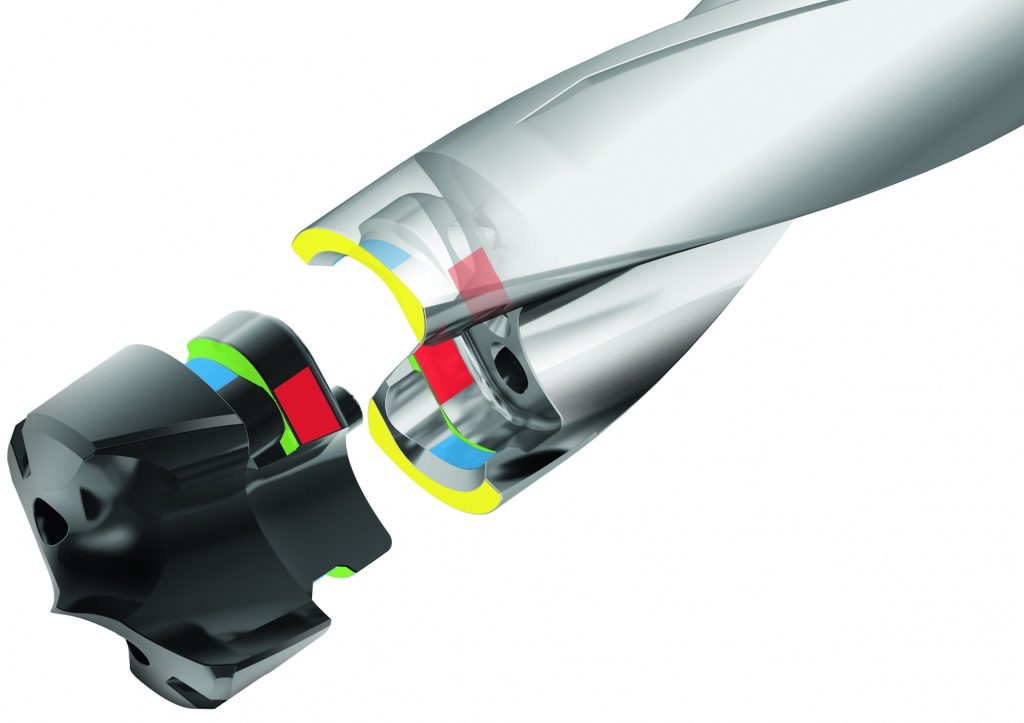

This is all cool stuff, but the KenTIP FS' biggest differentiator isn't its coolant delivery system, the new grades of carbide, its polished flutes or tip designs—it's the mounting interface. KenTIP FS has the robust insert security of the larger KSEM and KSEM Plus drills, but uses a quick-release mechanism similar to the one KenTIP users are familiar with—just clean the pocket with an air blast, set the insert in place and give it a slight twist, then secure it with the supplied smart wrench. It's not going anywhere. That's because the KenTIP FS has a patented taper interface that provides maximum rigidity and accuracy. Its retention lock eliminates pullout, and its large bearing surface is able to withstand extreme torsional loads without pocket deformation. And since the full solid-carbide insert has no

mounting screw, there's no risk of damage to the clamping mechanism from chip or workpiece contact.

Best of all, KenTIP FS is a sustainable solution. There's no need for reconditioning as there is with solid-carbide and many modular drills. Use the insert to its fullest capability, replace it with a fresh tool, and get money back when you recycle the old one using the Kennametal recycling service. There's none of the offset adjustments as there is with resharpened tools, or worry about how a used drill will perform compared to a new one. Tool life and production throughput are therefore more predictable, the company reports. And since the merry-go-round of drills out for grinding is now eliminated (never mind that inserts are much less expensive than solid-carbide drills), tooling costs are substantially reduced.

"The rigidity and stability of the KenTIP FS interface is crazy, and since the drill has a full solid-carbide front, the interface can withstand more heat and abuse than competing modular drill technologies. In addition to that the carbide tip fully covers and protects the steel holder from washing out. We simply put carbide where it matters," says Schmitt. "Granted, there will always be extremes where nothing but a solid-carbide drill will do, but for perhaps 90 percent of the applications we see, the new design works exceptionally well in a variety of materials. Kennametal

put a lot of time and effort into optimizing KenTIP FS, and we look forward to offering it to our customers."