KRPXng Rack and Pinion Systems

KRPXng Rack and Pinion Systems

In the last 10 years, the success of IBARMIA, a Basque firm manufacturing innovative machining centres for different sectors, is thanks to REDEX, who has provided the company with rack and pinion systems for the X-axis of its machine tools, according to the company.

In the last 10 years, the success of IBARMIA, a Basque firm manufacturing innovative machining centres for different sectors, is thanks to REDEX, who has provided the company with rack and pinion systems for the X-axis of its machine tools, according to the company.

Recently, IBARMIA selected the KRPXng model of gears. They have just fitted two machines with this system: the ZVH55-L8000 Extreme machining centre and the ZV58-L9200 Classic machining center. IBARMIA is a family-based company, mainly operating in the machine tool sector, offering high value-added solutions to meet the needs of their customers by adapting to their requirements. This customer-oriented approach has allowed them to evolve and survive in the market since their foundation, six decades ago, to the present day. With a team of young, dynamic, committed and motivated individuals, IBARMIA enthusiastically accepts the challenges posed on a daily basis from a double product-market perspective: in regards to the product, a firm commitment to innovation and a customer-oriented approach, and, with respect to the market, aiming to be present in those destinations with the greatest consumer potential (the European Union, the United States, China, India).

The dynamics emerges from an ambitious strategic plan which, in turn, is directed at the everyday activity of the company in order to minimise downtimes, risks to workers and environmental impact. In the last 10 years, IBARMIA's success has, in part, been due to their work alongside REDEX, who have provided, in addition to other solutions, the rack and pinion systems for the X-axis for a number of machining centres with high dynamic requirements.

Recently, the Basque Company selected the KRPXng model of gears. They have just fitted two machines with this system: the ZVH 55-L8000 Extreme machining center and the ZV 58-L9200 Classic machining center. REDEX's contribution and the application of the machining centers. As suppliers to IBARMIA for approximately 10 years, REDEX has provided "peace of mind from knowing we are in good hands," says Iñaki Murua, Head of Engineering for New Developments at IBARMIA. "There is a very high level of collaboration with the Design Department. We have direct access to the design office at REDEX at the headquarters in Paris, which helps to reduce the design times for new models and machines with special specifications." This helps to guarantee access to the latest market proposals. "REDEX is a pioneer company in the world of drive systems, giving us access to the latest developments in the world of drive systems," he concludes.

For example, "the ZVH Extreme model was designed as a general purpose machine while also being a high quality, capacity and accuracy machine," explains Murua. "The integration of machining processes into the IBARMIA MULTIPROCESS Series minimises the number of machines used and significantly reduces the machining time of complex pieces. The efficiency associated with MULTIPROCESS centres improves the quality of the piece, by using fewer machines and therefore, having fewer constraints; it reduces the cost of the initial investment as fewer machines are required, and the necessary floor space, and eliminates the transfer of pieces between machines, simplifying the industrial management," he concludes.

Rigidity as a key factor in the accuracy of linear and rotation axes "The movement of linear and rotation axes is critical in machine tools," says Arrate Olaiz, Director of Innovation for IBARMIA. "It allows the effective and controlled positioning of the tool and the pieces to be machined. Therefore, we are aware that rigidity is a key factor, and even more so in this machine, as the drive system has to move more than 8 t at 4 m/s2 and 45 m/min. With the REDEX drive systems, we have a positioning accuracy of about 0.005mm."

"Moreover," continues Arrate Olaiz, "the rack and pinion system has a lower moment of inertia, increased rigidity and performance. A major advantage with respect to ball screws is its modularity. Installation times are reduced, resulting in increased reliability. Given these displacement length conditions and levels of accuracy, ball screw transmission technology was rejected for use in such a dynamic machine, and so we selected the REDEX solution as a strategic supplier," he explains.

"Sixty percent of the total rigidity in a rack and pinion system is provided by the radial component of the gear, an area in which REDEX solutions stand out from their competitors," confirms Pedro Rebolledo, director of ANDANTEX Iberia, the associate of REDEX in Spain.

This extreme rigidity is an intrinsic aspect to the unique design:

• Concept of pinion integrated into the planetary system, where the cogs are machined directly on the axis.

• The distance between the contact point of the rack and the bearing support is as small as possible.

• The bearings are generously oversized.

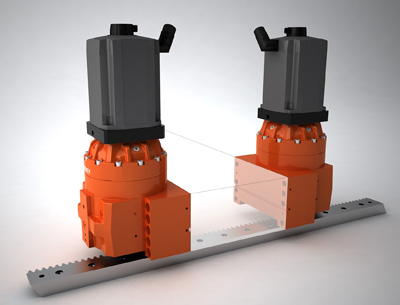

Thanks to these features, the REDEX rack and pinion systems have very high values of natural frequency. This allows development engineers to fit their machines with more solid bases in order to obtain high natural frequencies that result in higher accuracy levels and dynamics. This is also true for the rotation axes (rotary tables and face plates), where the gear rim is placed in the most technologically and commercially suitable position with respect to the worm gearbox and motor torques for diameters greater than 1 m. In this type of application, REDEX is also a pioneer in the market, and for several years IBARMIA has been benefitting from this in their machining centres for large diameter circular pieces. KRPXng is the renewed successful range of rack and pinion systems by REDEX, especially designed for gantry-type or moving column machine tools. The KRPX planetary gear is one of the best-known examples of the close collaboration between REDEX and their partners OEM, leaders in the machine tool sector.

Consisting of two planetary gears, the KRPX, TwinDRIVE solution is designed to adapt to both sides of the carriage or column of the machine. The electrical precharge guarantees the complete cancellation of angular play in the rack and pinion system. The values of radial rigidity cannot be equalled thanks to the already successful integrated output pinion-axis solution, exclusive to REDEX. The new version is already available in all sizes and includes the new HQ-GF gear finishing technology, which helps to reduce energy consumption thanks to a saving in performance losses of up to 15 percent in comparison to gears in accordance with the DIN 6 quality standard obtained from the cutting, saving thousands of kWh over the machine's service life. The use of the KRPXng gears in the ZVH55-8000 Extreme machining centre has resulted in significant savings in design and assembly. "REDEX has a variety of assembly configurations unique to the market. For this application, REDEX recommended the KRPX model. The exclusive cubic design of the KRPX gear casing resulted in significant financial savings with respect to the assembly of the cylindrical flange that we fitted in the first machine some years ago, as we have been able to dispose of the intermediate pieces used to fasten the gears, such as the brackets and adapter plates.

In addition to saving on these components, we have simplified the design, attaching the gears directly to the carriage, as if they were part of the structure of the machine itself, thus improving the rigidity of the assembly. This has resulted in further savings in design and assembly hours," explains Ander Aizpitarte, Industrial Director of IBARMIA. Leader in mechatronic solutions With a consolidated turnover of 50 million Euros, seven associates around the world, 320 employees and 50 percent of the turnover outside Europe, REDEX is a European leader in mechatronic solutions that provide critical components for ultra-high accuracy machines all over the world. Aircraft, cars and boats, in addition to wind turbines and energy plants are manufactured by the latest machine tools equipped with REDEX drive systems. REDEX offers engineering experience in a full portfolio of avant-garde products, that include: low-play planetary gears, high torque drive heads, rack and pinion systems for linear axes and pre-charged drive systems for milling and turning tables.

"REDEX offers integral solutions with a high technology value, including eco-design, energy efficiency and recyclability of components, aspects which, in today's world, are key factors for the leading machine tool manufacturers," explains Pedro Rebolledo: He goes on to say, "our manufacturing and internal test protocols give us total control over the level of product quality and help us to provide a better service to our customers. REDEX products are specifically conceived, designed and manufactured 100 percent in accordance with the machine tool quality and manufacturing standards. Consequently, together with continuous innovation and product improvement (8 percent of our turnover is allocated to R&D), this means that reliability and a long service life have become aspects that our customers take for granted."

"Beyond these aspects, our greatest advantage is our deep engineering know-how and our proven sales engineers," highlights Rebolledo. "Our product is especially technical. As a complement, we offer our customers an added value consisting in an integral technical service, from the selection of the drive system to assistance during assembly. We sell solutions, not only the product," explains Pedro Rebolledo.

In addition, REDEX has three strategic service centres in Europe, the USA and Asia, which form an ideal structure for the manufacturers of machines aimed at the global market, with respect to offering customers maintenance, training and local services. Ander Aizpitarte, Industrial Director of IBARMIA, positively values the pre- and after sales services of REDEX: "To offer our customers an efficient and competitive response, the service provided by our suppliers is essential and is something that we appreciate.

Moreover, we value the exclusive approach adopted by the engineers and sales representatives from REDEX towards the machine tool market. Firstly, we have the unconditional support of local engineers just 40 minutes away who always give us an immediate and personalised response. This is not in vain. The offer of a suitable service when selecting a drive system obviously helps to optimise the cost-performance ratio." The levels of costs and services offered by REDEX are an essential advantage for the new markets. The director of ANDANTEX Iberia is clear: "2013 is, undoubtedly, the year of mechatronics for REDEX.

Breaking through the walls between Measurement and Mechanical and Electrical Engineering is an avant-garde tendency that is revolutionising the sector. The automotive industry is leading the way with its hybrid cars and the construction of machines will continue along the same path. Energy efficiency, compactness and higher yields are the main vectors in which work is being carried out, and we are well-placed to meet these challenges. This is a commitment we have to our customers and we will show them in situ if they visit us at the EMO." ZVH Extreme fixed table and moving column machining centres

"Since 2001, we have turned our heads but face forwards," explains Arrate Olaiz, Director of Innovation for IBARMIA. "In 2001, we decided to include the B-axis or continuous head rotation in the significant advantages of our fixed table and mobile column machining centres. We applied the latest technology available in the market: transmission through a motor mounted on the rotation axis itself and direct measurement of the rotation in the same axis." The result was an extraordinary dynamic automatic recovery in the event of collisions and maximum accuracy in positioning and repeatability.