Lantek Global Release 2022

Lantek Global Release 2022

The 2022 update features significant improvements in flexibility, enabling the software to be adapted to individual production needs; usability, for a better user experience and process visibility; and efficiency and automation, reducing manual steps for faster processing.

Lantek, a multinational pioneer in the digital transformation of the sheet metal, metal cutting and processing industry, has incorporated over 80 new improvements and advances in its latest software version, Lantek Global Release 2022.

The 2022 update features significant improvements in flexibility, enabling the software to be adapted to individual production needs; usability, for a better user experience and process visibility; and efficiency and automation, reducing manual steps for faster processing.

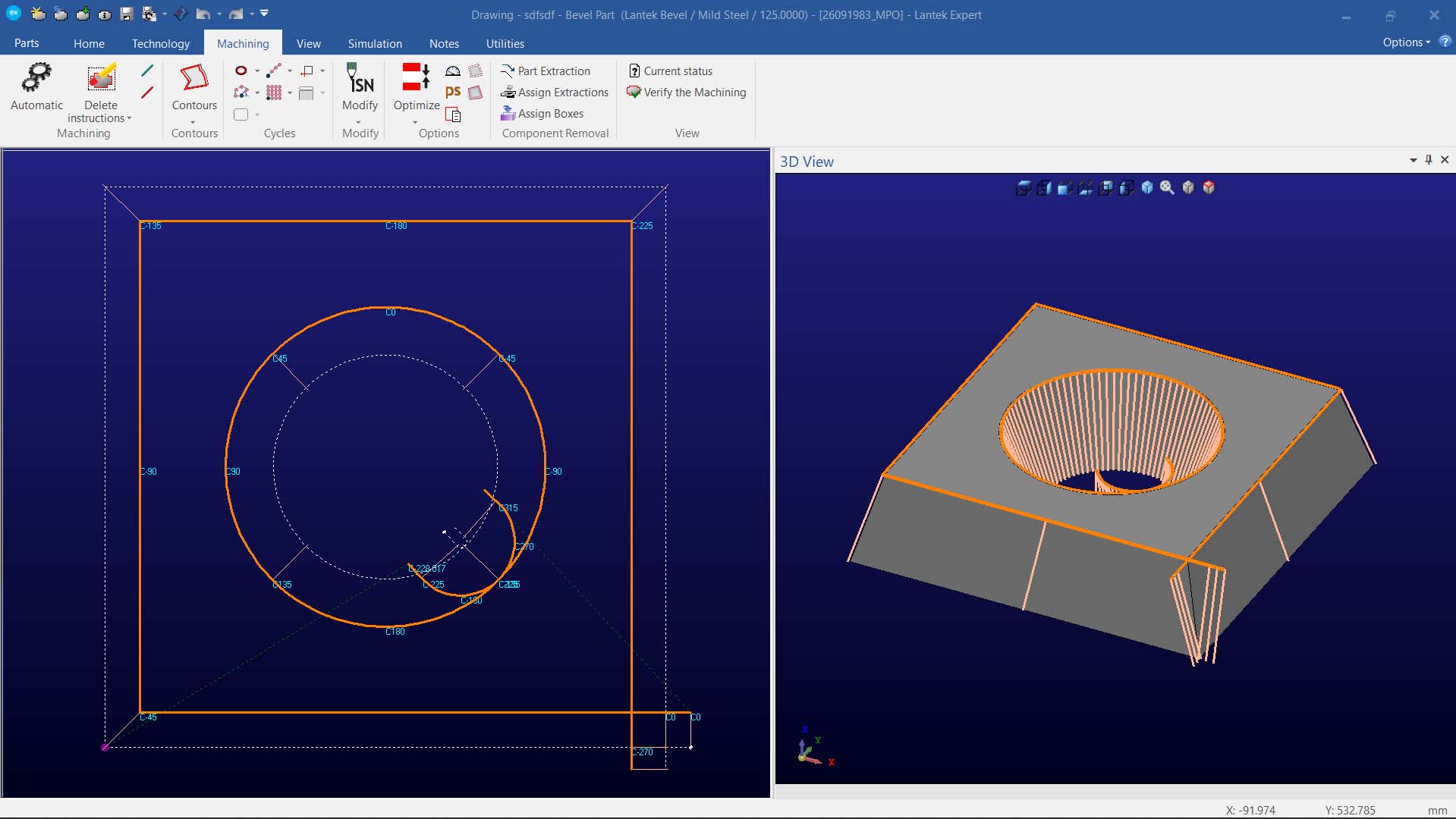

The Lantek Expert CAD/CAM nesting software solution has been improved to allow access from different areas of the system. A redesigned module allows automatic tagging technology to be applied, providing improved configuration options to adapt to any part geometry or cutting quality, avoiding the possibility of imperfections in the part.

The new version also facilitates the native interpretation of bending line technology from the import stage, as well as the automatic import of nests created by external systems including the automatic detection of repeated parts. Additionally, new options have been added for semi-automatic generation and modification of scraps.

Lantek Flex3d has been updated to work seamlessly with new machines, devices and technologies used to cut structural tubes and profiles. The new machine configuration module has been completely redesigned for faster system start-up on any type of machine. Further, its innovative process automation module allows users to easily create unattended or guided workflows, using the entire Flex3d architecture as a big "black box", with countless possibilities.

Lantek's new advanced milling technology management supports different tooling and cutting strategies for machines that incorporate this technology, expanding machining possibilities available.

Lantek MES and Lantek Integra handle workshop management by accurately tracking resource loading, orders, delivery dates, quality and stock levels. Its ability to maintain traceability and flexibility to react to changing circumstances is possible by improved capabilities in recording data related to downtime and reasons for part scrap during production. Operators are now able to record changes made to the sheet format used during nest creation, further maintaining traceability for any change within the software system.

In this new version, multiple improvements have been made to the Power Sync integration engine, to export production information from the MES to external systems for any type of operation.

Better integration between Lantek MES and Lantek Integra with Lantek Flex3D features new options for importing, nesting, and time and cost calculation in the tube/profile parts quoting module. Support for assembly quoting has also been improved, thanks to an intuitive ability to browse the entire assembly structure of components and the operations involved in the calculation of costs and prices for a quote.

Finally, Lantek Integra perfects material planning, thanks to the ability to pre-reserve" sheets or profiles in sales orders. This is fully integrated with the Warehouse and Purchasing modules, so the right material can be used later during the nesting process.

The commercial launch of Lantek Analytics in 2021 saw the incorporation of the first Software as a Service (SaaS) application to Lantek's product portfolio. This business intelligence application collects relevant business data on a daily basis. It can be accessed from any device at any time and allows users to see what is happening in the factory with more than 70 predefined KPIs and dozens of metrics and dimensions available. Improvements have been made to allow the creation and visualization of customized widgets and KPIs, as well as stability and performance improvements.

Juan José Colás, Lantek's Chief of Sales and Marketing Officer said, "After more than 36 years of history, at Lantek we continue to move forward and learn with the aim of improving our customers' experience. With this new version, we aim to have a greater impact on the productivity and visibility of companies, accompanying them on their journey towards digital transformation."