Latest Release of ALPHACAM Software

Latest Release of ALPHACAM Software

One of the major highlights of the latest release of ALPHACAM, from Hexagon Manufacturing Intelligence's Production Software business, are enhancements to the post-processor engine, delivering what is described as best-in-class, cutting-edge technology.

One of the major highlights of the latest release of ALPHACAM, from Hexagon Manufacturing Intelligence's Production Software business, are enhancements to the post-processor engine, delivering what is described as best-in-class, cutting-edge technology.

Brand Manager Hector Henry says: "We can confidently back up that claim, as the enhancements mean the post-processor engine directly configures and deploys a simulation session, resulting in more realistic motion, as well as the ability to support cycles such as M6, and additional hardware that has previously been underutilized or ignored. This new functionality is truly an Industry-first and will surely become a new standard."

The Automation suite has been enhanced, improving the user's experience and productivity when creating and deploying job configurations. Whether setting up a first automation job, or whether the user is involved in complex and dynamic environments, Henry says that the new Setup Wizards will make short work of daily production tasks.

Regarding solids machining, specifically machining solid faces directly, he says that most industry packages are only concerned with extracting features from solids. "ALPHACAM sets a new standard by allowing direct interaction with them. Previously, we enhanced our solids interaction by allowing users to saw a solid face directly. The Rough/Finish command (profiling) now allows the user to directly select and machine a solid face. And if your machine supports tool compensation on custom orientations (planes), this option provides the ability to create precision parts with minimal effort, via the use of G41/G42," Henry says.

Advanced 5-axis functionality has been updated to include numerous improvements. Two new key features include the ability to integrate the Toolpath Optimizer into a core cycle which can then be stored in a machining style and deployed with Automation, and Advanced 5-axis functionality has been updated to include Barrel Mill and Double Profile Tools. Improvements in SWARF machining, multiple-axis roughing and toolpath smoothing are also included in ALPHACAM 2020.0.

The geometry offset command is now intelligent and dynamic, making all operations more productive, whether the user wants to simply retain attributes and information on the geometry, or to completely re-assign machining cycle parameters to a newly created offset. "This new feature delivers an intuitive and simple way of changing toolpaths for everything from simple tasks, such as passing associative/dynamic profile machining data, to complex ones, including re-assigning a boundary to a 3D surfacing method," Henry says.

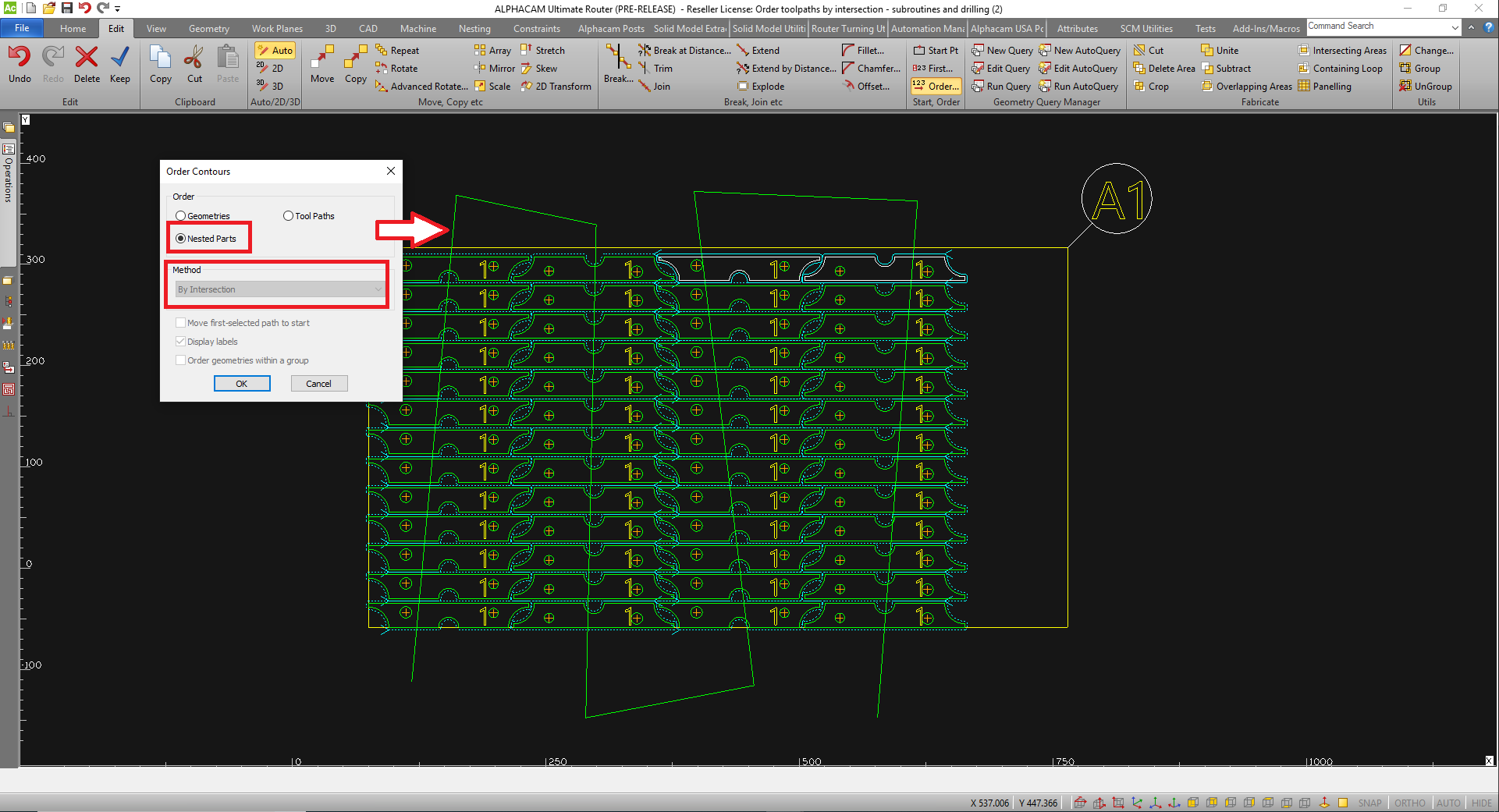

Regarding ordering and productivity tools enhancements, he says it is sometimes necessary to control the sequence of events and toolpath order with great care and precision, maybe requiring a preferred machining sequence to be added due to special considerations, such as hardware difficulties or lack of part hold-down. This new feature provides a simple, productive and effective way to set a user-defined order in seconds.

In conclusion, he says that ALPHACAM 2020.0 contains numerous key features essential to improving productivity for our customers working across the metalworking, woodworking, plastics and stone industries.