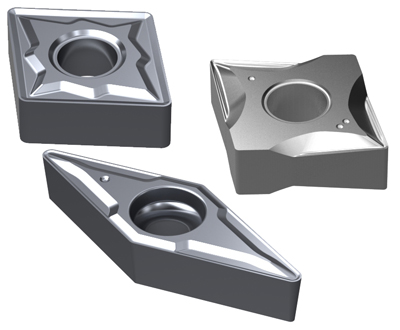

LT-Grade Insert

LT-Grade Insert

For the last 35 years insert manufacturers have created a vast array of insert grades, overloading the market with "specialized" insert choices.

For the last 35 years insert manufacturers have created a vast array of insert grades, overloading the market with "specialized" insert choices. The average insert drawer can contain dozens of different inserts. Because of this specialized nature inserts had assumed, machinists had to use a different grade for each material type, stock different inserts for each application, and change inserts for every material or application.

"For most shops, this means up to 50 percent of all the inserts they buy could be the wrong insert for the material," states Trent Moss, National Sales Manager, Nexus Cutting Tools, which are manufactured by Techniks. "Potentially, inserts could be run at the wrong speeds and feeds or not used to the end of their life.

"Nexus simplifies the insert game, continues Moss, "by offering an LT grade insert designed to perform in all materials, effectively rewriting the rules. With Nexus you always have the right insert for the job."

For Nexus users this could mean less down time spent changing tools, up to 50 percent fewer wasted inserts and significantly increased productivity, says Moss. The company offers free inserts for testing.