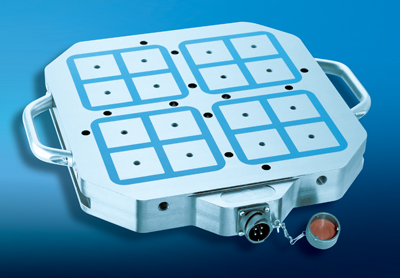

Magnos Magnetic Chucks with Vero-S Interface

Magnos Magnetic Chucks with Vero-S Interface

Combined with a SCHUNK VERO-S quick-change pallet system, MAGNOS magnetic chucks are more efficient, according to Schunk.

Combined with a SCHUNK VERO-S quick-change pallet system, MAGNOS magnetic chucks are more efficient, according to Schunk. The magnetic chucks can be exchanged in seconds at a repeat accuracy of less than 0.005mm. Also, if a magnetic chuck is clamped with a SCHUNK VERO-S interface, the highest clamping forces are ensured when the magnetic chuck is exactly positioned on the machine table.

Product features include: simple handling, precise repeat accuracy, tremendous reduction of set-up times, and flexible application possibilities. Control is done by a control unit which has to be ordered separately.

The unit is available in 480 volt with over 200 lbs clamping force per square inch. Standard sizes include 16 x 16 and 16 x 24. Custom sizes available upon request.