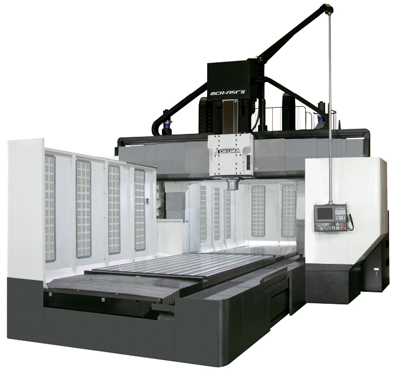

MCR-A5CII Double-Column Machining Center

MCR-A5CII Double-Column Machining Center

Okuma America Corp. unveils its newest double-column machining center, the MCR-A5CII.

Okuma America Corp. unveils its newest double-column machining center, the MCR-A5CII. With its multiple heads, the MCR-A5CII can now machine all five sides of a part from a single set-up. With this machine it takes only 2-3 set-ups to accomplish the same tasks that require 5-6 set-ups on a vertical machining center. This reduction in set-up time saves end users time and money, and also minimizes chances for costly errors.

The MCR-A5CII double-column machining center delivers true 5-sided machining in a compact footprint. The solid double-column construction ensures greater rigidity and closer tolerances, making this machine well-suited for the efficient machining of general parts and rapid die/mold jobs.

Features of the MCR-A5CII double column machining center include:

Improved productivity with higher machining capacity than its predecessor, the MCR-A5C

High accuracy and dimensional stability

Highly rigid ram-type spindle head

THINC OSP P300 CNC control for easy operation

Compact auto loading/unloading attachments for 5-axis machining

Compact footprint

The MCR-A5CII comes standardly equipped with Okuma's Thermo-Friendly Concept, which stabilizes thermal deformation and therefore shortens warm-up times and reduces the need for dimensional correction during production.