MCV-500H and MCV-5000H Laser System

MCV-500H and MCV-5000H Laser System

Optodyne Inc., Rancho Dominguez, Calif., a maker of laser measurement, calibration and compensation systems, recently introduced a new and improved laser calibration system—the MCV-500H and MCV-5000H. The MCV-500H and MCV-5000H laser calibration system is a basic system for linear displacement measurement, the company said in a news release issued Dec. 17, 2015.

Optodyne Inc., Rancho Dominguez, Calif., a maker of laser measurement, calibration and compensation systems, recently introduced a new and improved laser calibration system—the MCV-500H and MCV-5000H.

The MCV-500H and MCV-5000H laser calibration system is a basic system for linear displacement measurement, the company said in a news release issued Dec. 17, 2015. The system also works with accessories such as the SD-500 to perform 3D volumetric position error measurement, the AM-500 for angular error measurement, the LB-500 for dynamic circular contouring measurement, and the SP-500 for spindle error motion measurement.

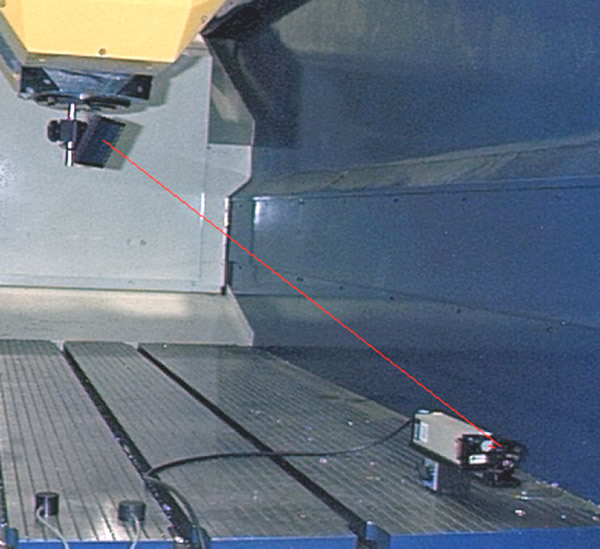

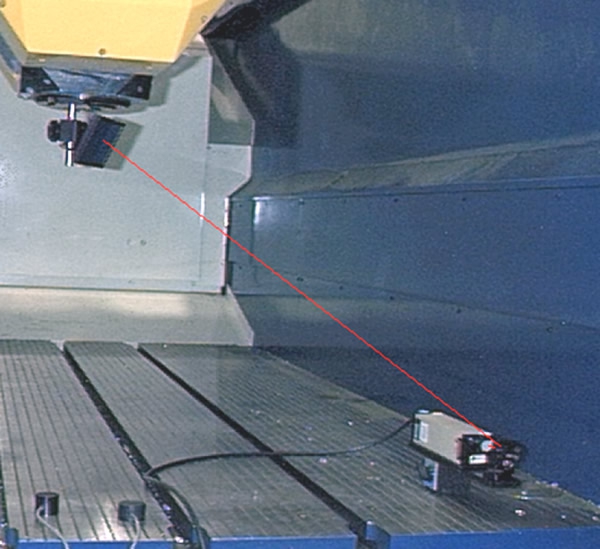

Shown is the MCV-500H being used for Laser vector measurement on a JOBS-LINK 5-axis linear motor machine. The laser head is on the bed and the flat-mirror is on the spindle.

The laser system, which registered a frequency stability rating of better than 0.02 ppm and is capable of achieving a measurement accuracy of more than 0.2 ppm, is said to be ideal for high precision machining centers, coordinate measurement machines, and nano metrology.

An improved optical design and measurement range of 100 m makes the system suitable for large, 5-axis gantry type machines or for nano metrology with multiple-pass, according to Optodyne. The system also is said to be ideal for the measurement of robot arm movements, thanks to an optical beam expander that enables a lateral tolerance of +/- 7mm.

Described as compact, easy to setup and operate, the system comes with carrying cases as well as data collection and processing software capable of generating pitch error compensation files for most controllers (Fanuc, Siemens, Forgo, Heidenhain, Mitsubishi).