Contact Details

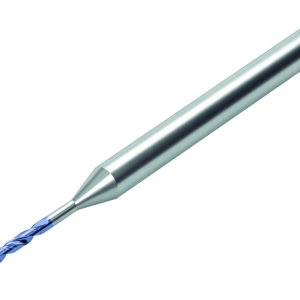

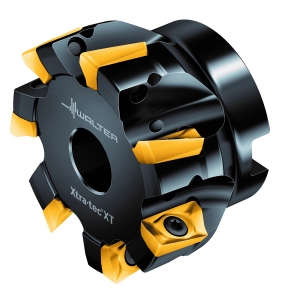

The new MD133 Supreme milling cutter from Walter, designed specifically for dynamic milling, delivers increased process reliability, particularly during unmanned operation. It reportedly boosts productivity thanks to a higher metal-removal rate and a reduction in machining time. The first in Walter's projected line of dynamic milling cutters, the MD133 Supreme has diameters of 0.25 to 0.75 in. (6 to 20 mm) and cutting lengths to 5 × Dc. They are designed for operating parameters typical of dynamic milling, such as a small width of engagement, and a high depth of cut facilitated by a large cutting length.

A chipbreaker guarantees short chips even when working with large cutting depths. This new milling cutter is available in two different grades: WJ30RD for steel (secondary application: cast iron) and WJ30RA for stainless steels (secondary application: ISO S, N). In addition to other benefits, the MD133 Supreme is a solution for applications with difficult-to-cut materials or unstable conditions (due to machine, workpiece, or clamping).

The new milling cutter's dynamic milling strategy makes full use of the entire cutting length, giving it an even wear pattern. In addition, heat is dissipated via the chip as much as possible, which leads to an improved tool edge life. Its special features make the MD133 Supreme interesting for high-volume production environments, but also to users with smaller batch sizes. With its high level of flexibility, thanks to its match to the demands of dynamic milling, render this milling cutter suitable for the diverse range of tasks required from these operations. Typical application areas for the new dynamic milling cutter line are general engineering, aerospace, energy and the mold and die industries.

Related Glossary Terms

- chipbreaker

chipbreaker

Groove or other tool geometry that breaks chips into small fragments as they come off the workpiece. Designed to prevent chips from becoming so long that they are difficult to control, catch in turning parts and cause safety problems.

- depth of cut

depth of cut

Distance between the bottom of the cut and the uncut surface of the workpiece, measured in a direction at right angles to the machined surface of the workpiece.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- metal-removal rate

metal-removal rate

Rate at which metal is removed from an unfinished part, measured in cubic inches or cubic centimeters per minute.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- stainless steels

stainless steels

Stainless steels possess high strength, heat resistance, excellent workability and erosion resistance. Four general classes have been developed to cover a range of mechanical and physical properties for particular applications. The four classes are: the austenitic types of the chromium-nickel-manganese 200 series and the chromium-nickel 300 series; the martensitic types of the chromium, hardenable 400 series; the chromium, nonhardenable 400-series ferritic types; and the precipitation-hardening type of chromium-nickel alloys with additional elements that are hardenable by solution treating and aging.

PRODUCTS

PRODUCTS