Contact Details

Walter has introduced the MD340 Supreme and MD344 Supreme solid carbide milling cutters for machining steel (ISO P). Despite a growing trend towards lightweight materials, steel machining still represents a significant market share.

The use of the tough milling grade WK40TP with multi-layer TiAlN and ZrN coatings ensures that these milling cutters provide exceptional performance when machining ISO P materials. In addition, these cutters are available with a reduced neck to enable reliable shoulder milling with an extremely high metal removal rate.

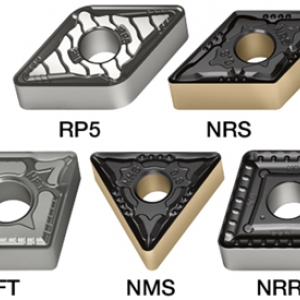

The MD340 Supreme has a diameter range from 1/16-3/4 in. or 2-25 mm and is specifically designed for roughing, full slotting and dynamic milling. The wide variety of products with three, four or five teeth makes the cutter extremely productive for universal application.

The MD344 Supreme is a four-flute mill with a special face geometry for optimal 90° plunging and steep ramping angles, setting new standards when it comes to plunging and pocket and cavity milling in a single operation. The diameter range is from 6-20 mm. The multiple operations that are performed by the MD344 Supreme can shorten machining time due to fewer tool changes, reduce the required tool spaces in the machine and reconditioning costs are also reduced because no additional boring tools are required.

The MD344 Supreme and the MD340 Supreme three-flute versions both feature a 38° helix, while the MD340 Supreme four-flute has a 39°/41° variable helix, the MD340 five-flute version features a differential or unequal pitch.

The variable helix, differential pitch versions are each perfectly coordinated, and adapted to the number of teeth, to ensure exceptional performance and operational smoothness, which in turn also improves the quality of the surface finish and maximizes tool life.

The Walter lineup of products consists of three categories to tools. Supreme tools indicate the highest level of technology and performance available. Advance tools indicate product efficiently balanced between price and performance and Perform tools are products that provide an economical solution with focused importance on price ideal for small batch volume jobs.

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- pitch

pitch

1. On a saw blade, the number of teeth per inch. 2. In threading, the number of threads per inch.

- slotting

slotting

Machining, normally milling, that creates slots, grooves and similar recesses in workpieces, including T-slots and dovetails.

- titanium aluminum nitride ( TiAlN)

titanium aluminum nitride ( TiAlN)

Often used as a tool coating. AlTiN indicates the aluminum content is greater than the titanium. See coated tools.

PRODUCTS

PRODUCTS