Mida Hyper Probing Software

Mida Hyper Probing Software

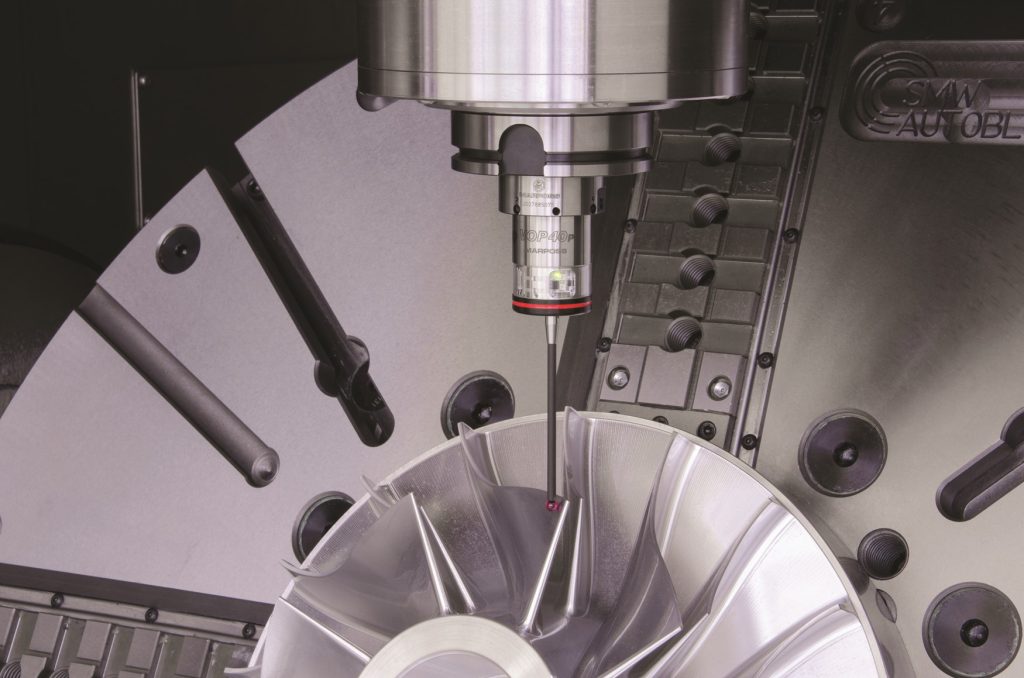

Marposs introduces Mida Hyper Probing — a software compatible with Marposs probes that calculates the best cycle time for machines simply by users entering repeatability range and workpiece positioning tolerance. This software can achieve an 80% reduction in cycle time, ensuring fast and precise probing.

Marposs introduces Mida Hyper Probing — a software compatible with Marposs probes that calculates the best cycle time for machines simply by users entering repeatability range and workpiece positioning tolerance. This software can achieve an 80% reduction in cycle time, ensuring fast and precise probing.

Hyper Probing can operate any compatible machine to its maximum production capacity. Its key functions include Smart Calibration, Smart Approach and Smart Retraction, which optimize cycle time and guarantee system repeatability. With Smart Calibration, Hyper Probing calculates and customizes machine performance using an Auto-Learning algorithm, which optimizes cycle time and productivity.

Smart Approach provides single or double touch measuring strategies and maintains the required repeatability threshold, allowing the system to independently choose the fastest touch solution.

Smart Retraction is used with the double touch algorithm, ensuring the probe exists the workpiece and returns to the idle position. This allows measurements to be made during axes acceleration ramps and avoids useless probe open alarms.

Overall benefits include:

- Maximization of good/reject workpiece ratio

- Minimization of cycle time for each workpiece

- Up to an 80% reduction in measuring cycle time

- Required repeatability threshold guaranteed

- Machine limits observed, guaranteeing maximum productivity