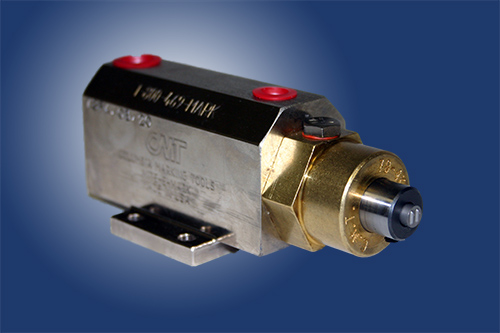

Mite-E-Mark Air Impact Marker

Mite-E-Mark Air Impact Marker

Columbia Marking Tools offers many new features on the popular Mite-E-Mark air impact marker. Additional features include: additional stroke length, integrated position sensors and a low maintenance non-lube feature. This air impact marker is commonly used for economically marking lot codes, acceptance marks or machine ID codes on metal and plastic parts. They may also be used in staking, seating or assembly operations.

Columbia Marking Tools offers many new features on the popular Mite-E-Mark air impact marker. Additional features include: additional stroke length, integrated position sensors and a low maintenance non-lube feature. This air impact marker is commonly used for economically marking lot codes, acceptance marks or machine ID codes on metal and plastic parts. They may also be used in staking, seating or assembly operations.

The Mite-E-Mark is a compact marking tool. It's smallest configuration is only 3" long, and has 1" of approach stroke from the retracted position to the point of part marking. The Mite-E-Mark now offers an additional option with longer approach stroke. This added feature also has more force. The 2" approach stroke model offers 2,200 lbs of impact force at 80 psi.

As systems become more and more automated, Columbia Marking Tools has added more updated technology to the simple air impact marker designs. One of the most recent added options to the Mite-E-Mark is the integrated position sensor. This electronic indicator is installed internally and is able to detect when the marker is in the retract position. This option is a favorite among designers of "lights out," or fully automated applications.

A new cost saving option is also now available for the Mite-E-Mark. The non-lube version of this air impact marker has permanent lubrication and improved seals. This combination provides a system that no longer requires constant maintenance and additional lubrication.