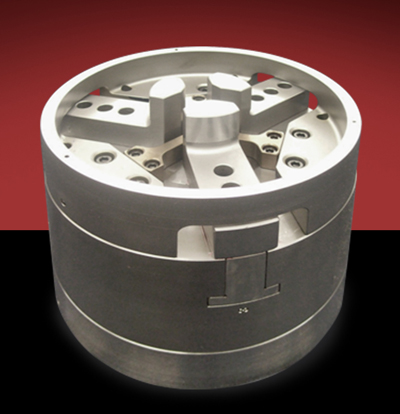

Model 625 Sliding-Jaw Air Chuck

Model 625 Sliding-Jaw Air Chuck

Northfield Precision Instrument Corp. specializes in developing custom solutions for difficult problems. In this case, the customer needed grip on the IDs of CVT transmission sheaves for runout inspection. To this end, Northfield developed the Model 625 sliding-jaw air chuck (0.0001" TIR) with special top tooling attached.

Northfield Precision Instrument Corp. specializes in developing custom solutions for difficult problems. In this case, the customer needed grip on the IDs of CVT transmission sheaves for runout inspection. To this end, Northfield developed the Model 625 sliding-jaw air chuck (0.0001" TIR) with special top tooling attached.

Top jaws are permanently mounted onto the chuck's master jaws to grip the ID of the part's central bore. An air-detect axial locator (three air holes evident in its top surface) was incorporated to ensure proper seating of the part upon robot-arm placement onto the chuck. This chuck is capable of .0001" TIR total accuracy/repeatability on all critical surfaces that interface with the part.