Multiaxis Machining

Multiaxis Machining

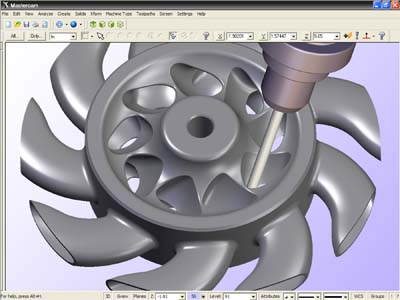

Multiaxis machining can dramatically increase a shop's competitiveness, and Mastercam's multiaxis machining offers a wide range of multiaxis machining strategies – both basic and advanced.

Multiaxis machining can dramatically increase a shop's competitiveness, and Mastercam's multiaxis machining offers a wide range of multiaxis machining strategies – both basic and advanced. With Mastercam, users have control over the three crucial elements of multiaxis machining: toolpath types, tool motion and tool axis.

Mastercam's multiaxis machining offers many toolpath types and features to simplify programming including:

- Machine 5-axis parts using spiral, zigzag or one-way tool motion

- Swarf fanning and swarf machining over multisurface floors to keep the tool edge against the drive surface for a smooth finish

- Multisurface 5-axis roughing and finishing, including depth cuts, plunge roughing and flowline machining

- Minimum tilt control, which helps prevent tool motion that would cause toolholder collisions

- Special options for machining cylinder heads and converting probe data to machinable geometry

Mastercam's multiaxis machining gives control over the tool axis, lead/lag, entry/exit and tilt. Full entry and exit control lets you determine exactly where and how the cutter enters and leaves your part. There is an automatic point generator, which adds greater precision, as well as advanced gouge checking and a 5-axis safe zone around the part.

Powerful axis limits control tool motion between defined angles, ensuring that the tool tilt will not violate part or machine tool limits. You can easily refine control of your tool axis with a few simple pieces of CAD geometry, and shank containment simplifies cutting in confined areas.