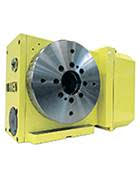

NCT200 CNC Rotary Table

NCT200 CNC Rotary Table

Unique to Nikken rotary tables is the innovative and patented carbide worm system comprised of a carbide worm screw, ion nitrided worm wheel (HV930), and hardened steel bearing surface (HRC58-60). The V grade solid carbide worm screw helps to ensure high rigidity and virtually eliminates wear. Compared with traditional worm system combinations (consisting of phosphorus bronze and aluminum bronze), wear is reduced by up to 8 times, and overall accuracy is substantially increased. Additionally, the worm wheel has specially hardened, ion-nitrided treated teeth that eliminate sliding friction.

Lyndex-Nikken, manufacturer and provider of high-performance machine tool accessories, announces the new NCT200 CNC rotary table offering high clamping torque in a compact footprint.

Nikken's NCT200 CNC rotary table boasts high indexing accuracy, repeatability, and exceptional braking force due to its advanced 663 ft. lbs. (900Nm) clamping system. This impressive clamping, combined with improved indexing, enhances machining productivity.

The NCT200 rotary table's new drive system increases rigidity by 25% compared to previous models, ensuring long-term accuracy and precision for machining. This design also reduces overall maintenance cost.

Key features of the NCT200 CNC rotary table include:

Advanced clamping system with 663 ft. lbs. (900Nm) torque enables reliable indexing accuracy

- High rigidity of new drive system ensures long-term accuracy and precision

- High speed Z Type rotary table is also available to reduce cycle time and enhance productivity

- Customization is available for face plates, rotary joints, angular plates, and support tables

Specifications of the NCT200 CNC rotary table include: diameter of table is 7.87" (200mm) with face plate and 5.12" (130mm) without face plate, clamping torque for braking system is 663 ft. lbs. (900Nm), and indexing accuracy is ±20 sec.

Nikken rotary tables are recognized worldwide for their wear-resistance, rigidity, and high-speed rotation. Nikken rotary tables are designed and built to provide high accuracy, increased production, and a trouble-free long life.

Unique to Nikken rotary tables is the innovative and patented carbide worm system comprised of a carbide worm screw, ion nitrided worm wheel (HV930), and hardened steel bearing surface (HRC58-60). The V grade solid carbide worm screw helps to ensure high rigidity and virtually eliminates wear. Compared with traditional worm system combinations (consisting of phosphorus bronze and aluminum bronze), wear is reduced by up to 8 times, and overall accuracy is substantially increased. Additionally, the worm wheel has specially hardened, ion-nitrided treated teeth that eliminate sliding friction.