NESTINGWorks 2016

NESTINGWorks 2016

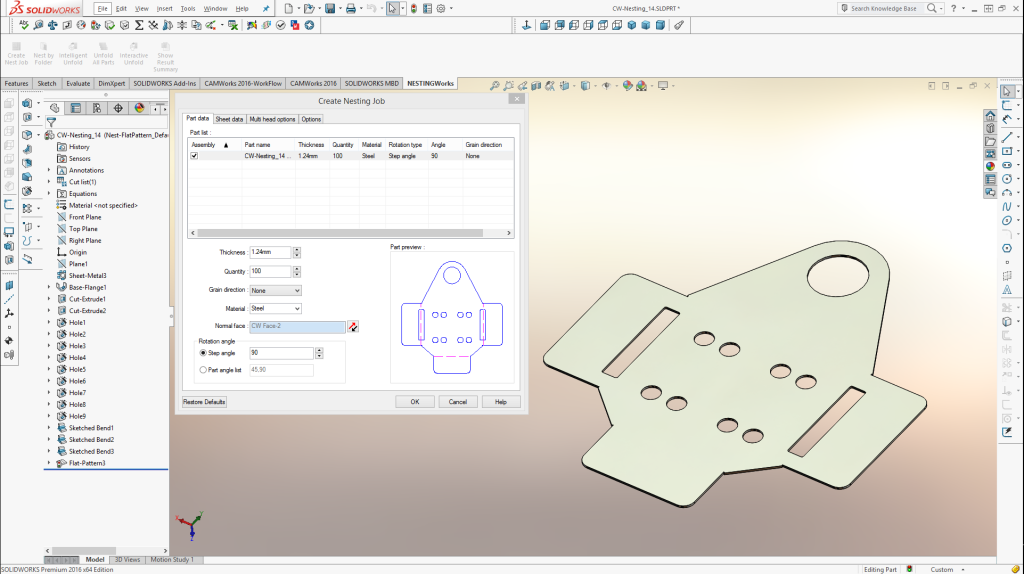

Geometric Americas Inc., Scottsdale, Ariz., recently announced the release of NESTINGWorks 2016, new 3D software for automatically nesting layouts of SOLIDWORKS parts and assemblies for production. Integrated within SOLIDWORKS 2016 software, the new application enables automated nesting of flat or 3D part or assembly models made from sheet stock, including sheet metal, plates, plastics, composites and wood, according to the company.

Geometric Americas Inc., Scottsdale, Ariz., recently announced the release of NESTINGWorks 2016, new 3D software for automatically nesting layouts of SOLIDWORKS parts and assemblies for production. Integrated within SOLIDWORKS 2016 software, the new application enables automated nesting of flat or 3D part or assembly models made from sheet stock, including sheet metal, plates, plastics, composites and wood, according to the company.

NESTINGWorks software leverages Geometric's NESTLib true-shape 3D technology, which is said to be one of the fastest and most fully featured automatic true-shape nesting libraries available in the industry, according to a Geometric news release dated Jan. 27. With NESTINGWorks, product designers reportedly can efficiently optimize sheet-stock layouts—including specifications for grain direction—so they can produce the maximum number of parts from a single piece of raw material in minutes.

"The combination of SOLIDWORKS design, NESTINGWorks nesting, and CAMWorks machining software provides us with a real competitive advantage because we can cut higher quality parts on our laser cutter in less time while optimizing material usage," said Mike Buchli, vice president of Karl W. Schmidt & Associates, a leading manufacturer of custom recycling systems. "Because CAMWORKS and NESTINGWorks are integrated inside SOLIDWORKS, the time and cost savings associated with the seamless process enables us to reduce our prices significantly, which helps us win more business."

NESTINGWorks software provides 3D true-shape layouts that allows designers to nest parts of varying thicknesses, the company explained. The software also is compatible with all downstream machining and manufacturing applications. Combined with SOLIDWORKS design configuration tools, designers can use NESTINGWorks to nest multiple sets of assembly and part variants from a single SOLIDWORKS model.

The new software reportedly includes:

- a single dialog box for ease of use;

- a fully automatic true-shape nesting solution to optimize placement of parts on sheet;

- the ability to automatically nest multiple parts based on the material and thickness, thus eliminating the manual effort of segregating individual parts;

- part-in-part nesting to fully optimize material usage;

- a user specified grain direction to easily manage required material properties; and

- full associativity with SOLIDWORKS software. Updates are tracked, and flagged whenever a change is made to the component and are reflected instantly