New EtherCAT G Gigabit Communication Technology

New EtherCAT G Gigabit Communication Technology

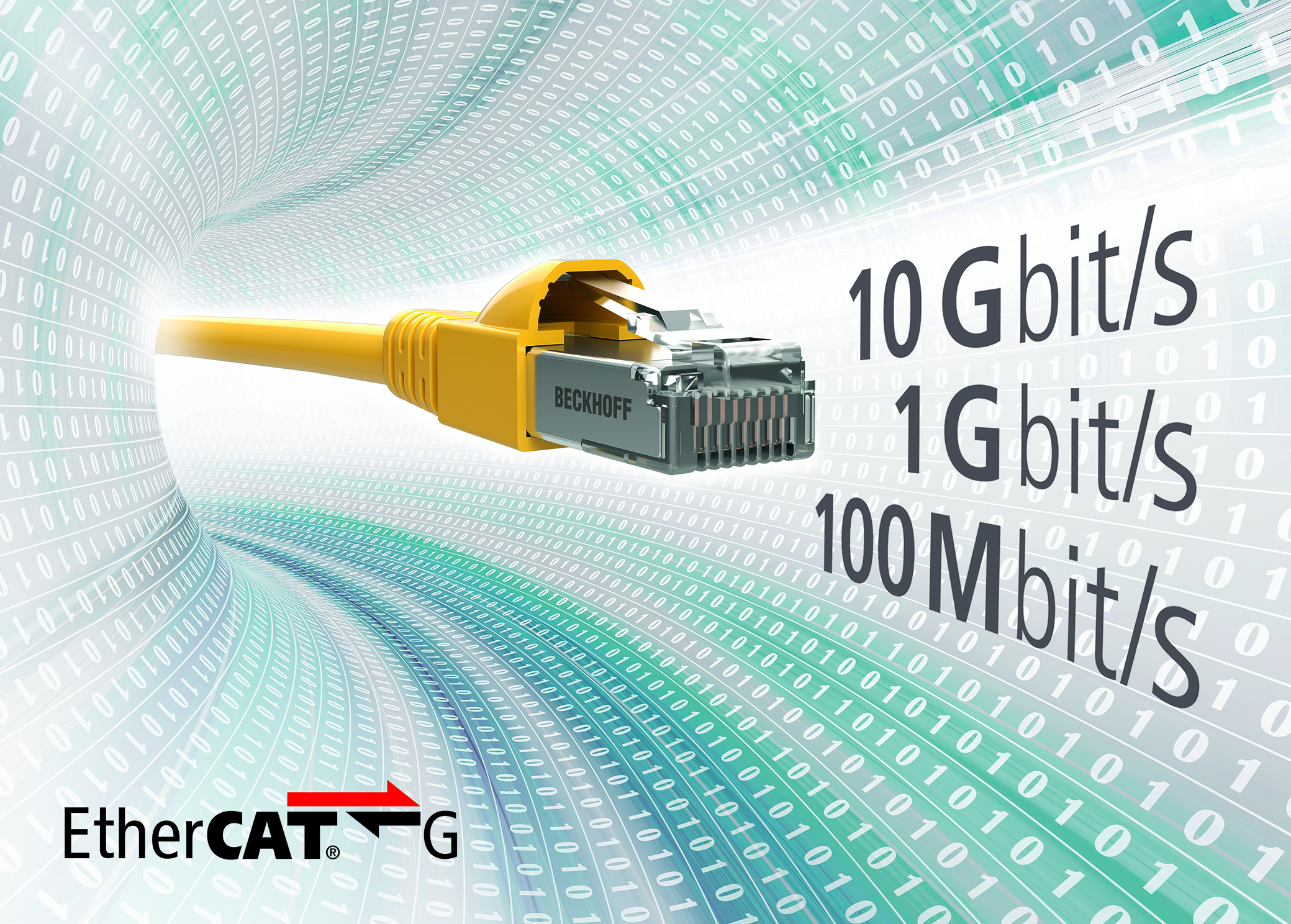

Beckhoff Automation has announced new EtherCAT G gigabit communication technology, which enhances EtherCAT performance by delivering the Gbit Ethernet speeds needed to support highly data-intensive applications. The latest industrial Ethernet technology expansion is not only compatible with the globally established 100 Mbit/s EtherCAT standard, but also provides the same familiar ease of use.

Beckhoff Automation has announced new EtherCAT G gigabit communication technology, which enhances EtherCAT performance by delivering the Gbit Ethernet speeds needed to support highly data-intensive applications. The latest industrial Ethernet technology expansion is not only compatible with the globally established 100 Mbit/s EtherCAT standard, but also provides the same familiar ease of use. In addition, the new branch controller model for EtherCAT G enables efficient operation of multiple network segments in parallel.

EtherCAT G supports standard Ethernet transmission rates of 1 Gbit/s; its EtherCAT G10 counterpart, already introduced as a proof-of-concept technology study, is even faster with data rates of 10 Gbit/s. The sharp increase in transmission rates beyond the standard 100 Mbit/s provided by EtherCAT significantly increases the possible data throughput. With propagation delay times through devices as a limiting factor on the one hand, but boosted by the newly introduced branch model on the other, EtherCAT G can deliver a two-to-sevenfold performance increase, depending on the application.

"EtherCAT G and G10 raise performance to entirely new levels that will enable our customers to build the best, highest-performing machinery in the world," Managing Director Hans Beckhoff comments. "EtherCAT G and G10 are not meant to replace the highly successful EtherCAT standard based on 100 Mbit/s Ethernet. The new performance levels are intended as system-compatible expansions."

Exceptional performance and ease of use have always been the hallmarks of the EtherCAT protocol. Though it is not a substitute for standard EtherCAT, EtherCAT G shares the same characteristics, yet achieves even higher transmission speeds without changes to the protocol or the EtherCAT master software. Fully compatible with the globally established EtherCAT standard, EtherCAT G provides the same field-proven capabilities, including built-in diagnostics, high-precision synchronization and, most importantly, unrivalled telegram processing on the fly. It also conforms to the IEEE 802.3 Ethernet standard.

The high performance offered by standard EtherCAT remains more than sufficient for the majority of today's applications. EtherCAT G has been developed specifically in anticipation of extremely large-scale applications and greater use of highly data-intensive equipment, such as machine vision cameras, complex motion control systems and measurement equipment operating with high sampling rates.

EtherCAT and EtherCAT G can be combined within a heterogeneous network. This means that EtherCAT G slaves can operate in a 100 Mbit/s EtherCAT network, and vice versa. In both instances, EtherCAT G equipment falls back to the 100 Mbit/s rate. With the new EtherCAT G branch controller model, though, EtherCAT branches can be set up to enable the parallel operation of 100 Mbit/s segments within a 1 Gbit/s network through a conversion of transmission rates. For instance, the upcoming EK1400 EtherCAT G Coupler can create a branch that steps the data rate down from 1 Gbit/s to 100 Mbit/s, making available the wide range of standard EtherCAT Terminals for use as I/Os on an EtherCAT G network. Based on the branch controller capabilities of the EK1400, the 1 Gbit/s data rate on the EtherCAT G trunk remains unaffected.

Another advantage of the EtherCAT G branch controller system is that it minimizes propagation delays. The new CU14xx branch controller series is designed specifically to interconnect EtherCAT and EtherCAT G segments and enable parallel operation. This setup significantly reduces signal propagation times and, thus, shortens communication and cycle times, because telegrams coming back from a given segment travel straight from the branch controller to the master at the higher transmission rate of 1 Gbit/s, independent of other network segments.