NITEGLOW Two-Stage Safety Nosing

NITEGLOW Two-Stage Safety Nosing

Wooster Products' new NITEGLOW treads with high-quality photoluminescent are ideal for exit path markings, steps and leading edge of landings when finding pathways in the dark is a necessity. This two-stage anti-slip stair nosing meets NYC Local Law 26, 2015 IBC, and 2015 IFC code compliance and is well suited for either new construction or retrofit interior stair applications.

Wooster Products' new NITEGLOW treads with high-quality photoluminescent are ideal for exit path markings, steps and leading edge of landings when finding pathways in the dark is a necessity. This two-stage anti-slip stair nosing meets NYC Local Law 26, 2015 IBC, and 2015 IFC code compliance and is well suited for either new construction or retrofit interior stair applications.

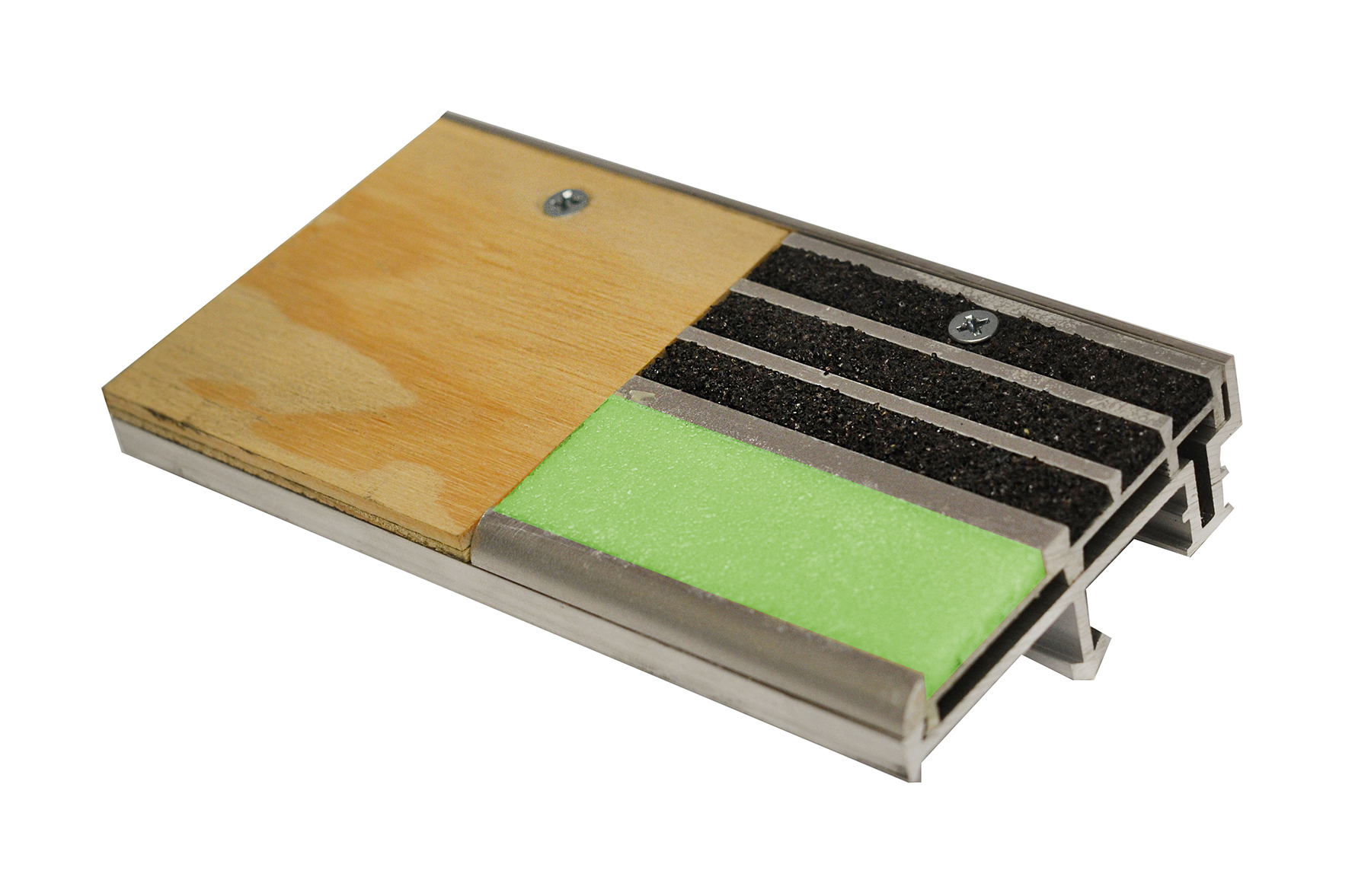

Heat-treated corrosion resistant aluminum substrate and a nearly diamond-hard aluminum oxide filler assures long tread life under heavy pedestrian traffic. Bright, long lasting photoluminescent epoxy filler is free of hazardous and radioactive substances, extends uniformly throughout the filler. A high content of aluminum oxide abrasive provides traction and long service life, and is replaceable. Available in lengths to order, to a maximum of 8'0". Clean architectural lines ensure aesthetic appeal.

NITEGLOW® two-stage safety nosing includes a replaceable anti-slip abrasive-filled top insert, and a mill finish extruded aluminum base, with sure-hold anchor. Optional wood insert keeps aluminum base clean during initial construction. Protective tape also available.

Anti-slip filler includes approximately 60% virgin grain aluminum oxide abrasive which is available in contrasting colors. Photoluminescent epoxy binder is a fully cured resilient epoxy with a filler ratio of 16% minimum for enhanced cleanability.