Online Robot Library

Online Robot Library

The online Robot library now includes 675 components from brands such as KUKA, Fanuc, ABB, TeknoMotor, AMB (Kress), SCHUNK, OnRobot, Joulin, Schmalz, Regal, Universal Robots, Güdel, Meltio, among others.

In 2022, the number of models in the online Robot library was increased by three times.

SprutCAM X Robot software, developed by SprutCAM Tech Ltd. in Limassol, Cyprus, provides a convenient and natural programming environment that simulates the interaction between an engineer, robot, tool, and product as closely as possible.

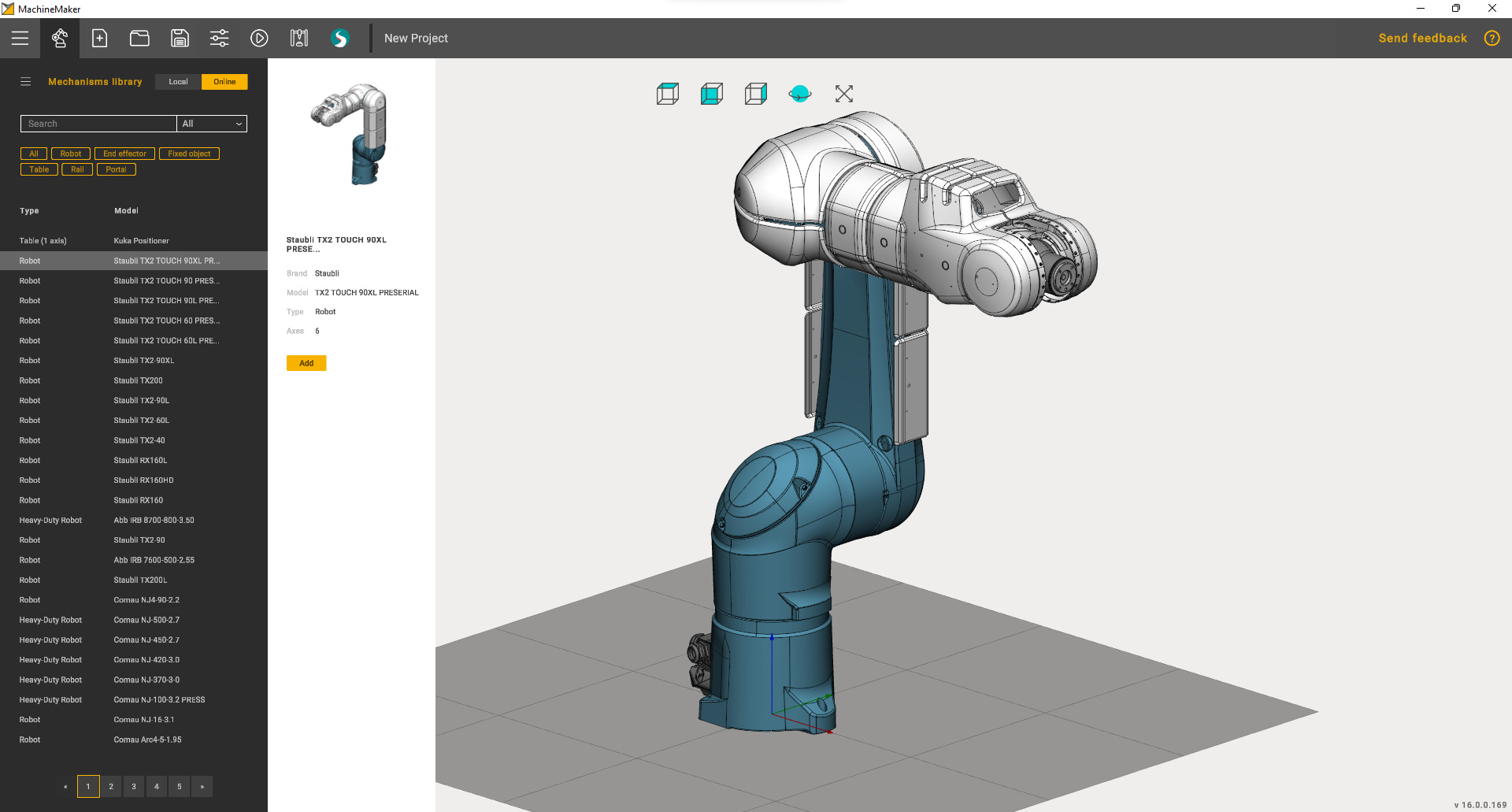

To develop a control program for an industrial robot and simulate all robot functions in a virtual environment, a technologist-programmer needs to create a realworld cell with robot equipment and production components in a CAM system or integrate a cell from external software. The Machine Maker add-on, a zero-code robot cell builder for SprutCAM X, allows manufacturers and integrators to quickly create an accurate digital twins of any robotic cell using an online library that supports the largest selection of industrial robot brands.

The online Robot library now includes 675 components from brands such as KUKA, Fanuc, ABB, TeknoMotor, AMB (Kress), SCHUNK, OnRobot, Joulin, Schmalz, Regal, Universal Robots, Güdel, Meltio, among others:

- Robots, including heavy-duty and cobots

- Single axis, 2-axis and 3-axis positioners

- Actuators, including moving grippers (end effectors)

- Railing

- Fixed objects such as tables, controllers, and fencing

The developers team at SprutCAM Tech keeps the library up-to-date with the most popular equipment. Manufacturers and integrators can request to add a 3D model of a robot or another piece of equipment to the MachineMaker online library by emailing [email protected].