P4.1 Roller Chain

P4.1 Roller Chain

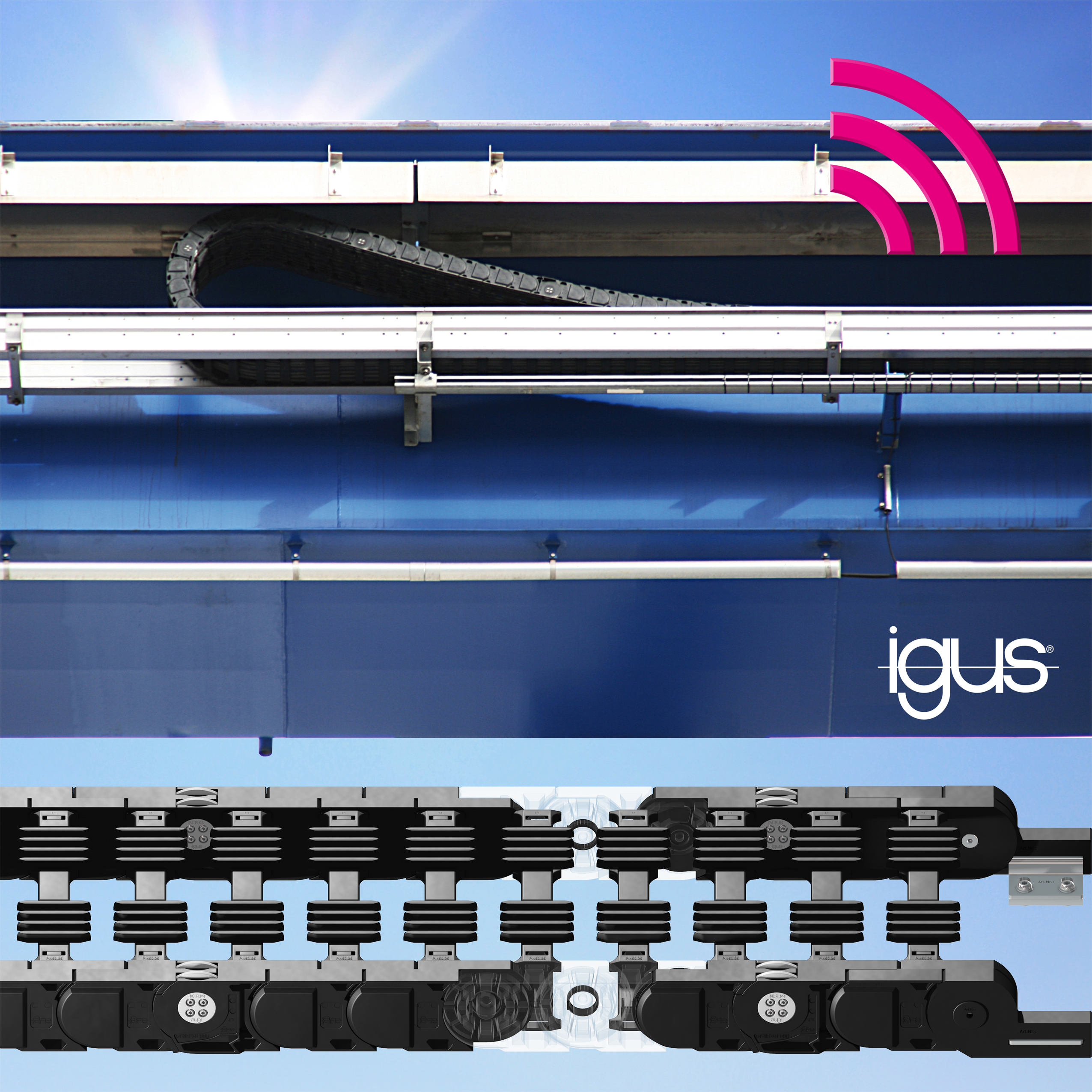

Motion plastics manufacturer igus introduced new tribologically optimized plain bearings that ensure lubrication-free mounting of individual chain links, which will increase the uptime of crane systems and gantries.

Motion plastics manufacturer igus introduced new tribologically optimized plain bearings that ensure lubrication-free mounting of individual chain links, which will increase the uptime of crane systems and gantries.

The P4.1 roller chain for long travels also has the option of the igus' predictive maintenance concept with a new isense wear sensor.

The P4 system from igus has been the solution for demanding applications for many years. The P4 roller chain has proven itself in more than 1,000 crane and gantry applications worldwide, with travel distances of up to 800 meters, high speeds of more than five meters per second and several million cycles with low vibration and noise.

Using rollers integrated in the chain link, the friction is reduced to a minimum and the service life prolonged to the maximum. Due to the offset between the upper run and lower run, the plastic rollers are not rolled over, but roll past each other to allow for smooth and efficient operation.

As a result, the coefficient of friction decreases and the drive power is reduced by 57 percent. Users such as ZPMC, the world's largest crane manufacturer, have been relying on the reliable profile roller chain for many years. With the new lubrication-free and maintenance-free plain bearings made of high-performance plastics, igus has now developed the e-chain even further.

igus has been developing and producing high-performance plastics for lubrication-free plain bearings and tough e-chains since 1964. Through the experience in both areas and the research of new plastic compounds, igus developers were able to significantly increase reliability of the P4.1 roller chain.

The chain includes a pin bore connection point for pivoting in every chain link connection. The pin bore connection point has been re-equipped with a maintenance-free tribo-polymer plain bearing, which more than doubles the service life. With this advancement, container cranes in ports, for example, can now achieve a service life of more than 15 years or 20,000 plus operating hours with low maintenance and high reliability.

Smart monitoring sensors, such as a wear sensor for the newly-installed plain bearings, can be equipped on the new P4.1. The sensor can send a signal to the igus icom communications module and maintenance can be planned in advance. Depending on the customer's requirements, the data of the icom module can integrate directly into the existing software environment and intranet systems for a maintenance message or can connect to the igus data center for an intelligent and dynamic service life prediction. In this case, the maintenance recommendations via Machine Learning and Al algorithms are constantly compared and defined with the data from many existing applications.

With the intelligent networking of the P4.1 roller chain, a maintenance engineer can access the service life data of the energy chain at any time and at any location.