P90CD and P90iC Horizontal Hobbing Machines

P90CD and P90iC Horizontal Hobbing Machines

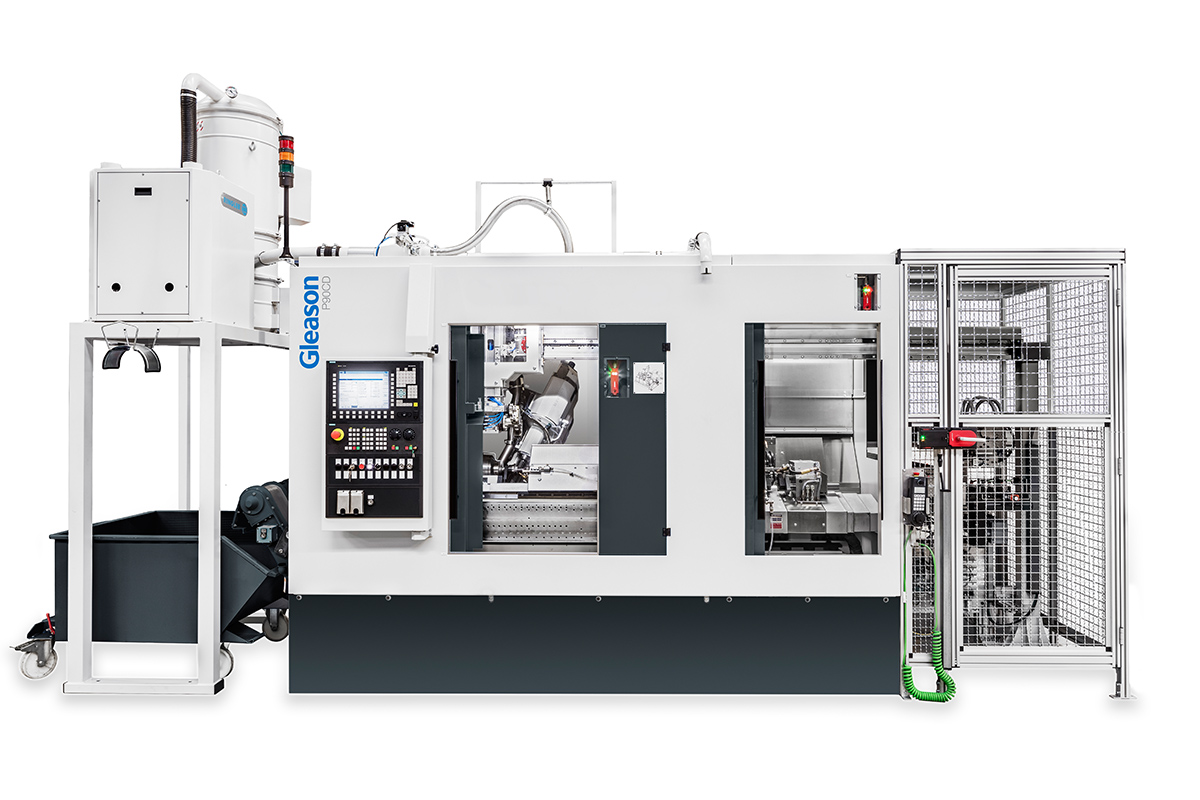

Gleason Corp. introduces the P90CD and P90iC horizontal hobbing machines. Now, two new machines from the P-Series enhance the current model line to provide optimized solutions for specific applications which require high productivity and efficiency.

Gleason Corp. introduces the P90CD and P90iC horizontal hobbing machines. Now, two new machines from the P-Series enhance the current model line to provide optimized solutions for specific applications which require high productivity and efficiency.

Based on the well known P90 hobbing machine, the new P90CD hobbing machine with integrated chamfering/deburring module has been designed for disc-type workpieces, like automotive pinions and short shafts. The P90CD features an integrated CNC chamfering/deburring station, which works in parallel to the cutting process; hence productivity is not compromised by the added auxiliary process. The P90CD can hob parts up to a diameter of 60 mm and module 3 mm; larger diameters are available on request. Cycle times are as short as 10 seconds for planetary pinions. The chamfering/deburring station includes an auto-meshing feature, which avoids tooth-on-tooth cut workpieces and chamfering tools for consistent cycle times and to avoid damage to workpieces.

The new P90iC hobbing machine with integrated chamfering/deburring unit has been specifically designed for the hobbing and quality chamfering/deburring of geared shafts, but can be used for disc-type workpieces as well. The P90iC features an integrated chamfering/deburring unit, which eliminates burrs and creates even and precise chamfers. The P90iC handles any workpiece up to a diameter of 100 mm and module 3 mm; larger diameters and modules are available on request. The P90iC is an excellent solution to employ one or two-cut processes for finish hobbing or to create a quality base for subsequent hard-finishing operations. The two-cut process in particular is executed in a single setup (cutting-chamfering/deburring-cutting) and eliminates secondary burrs and residue on the gear flanks. This process is very beneficial for subsequent hard-finishing processes, protecting the tool life of expensive finishing and dressing tools, especially if a honing process is applied.

For both machines direct-driven hob head options are available, which offer the optimal adaption to many applications. For both machines Gleason provides hobs from state-of the-art materials, with the latest wear coatings and high-quality rotary chamfering/deburring tools with extremely long tool life as well as clamping fixtures to secure high machining quality.