PartInspect L 3D Measurement Cell Product

PartInspect L 3D Measurement Cell Product

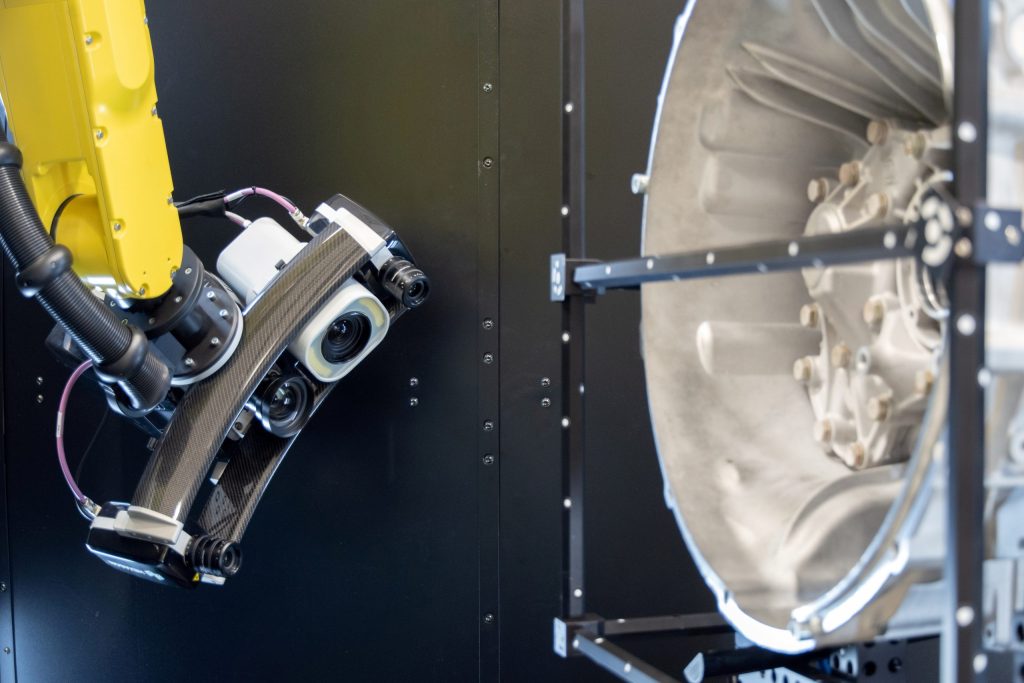

Hexagon's Manufacturing Intelligence division announced the worldwide launch of PartInspect L, the first automated 3D measurement cell product based on AICON scanner technology. Featuring a choice of structured-light scanning technology paired with a flexible robot arm and housed within a modular cell format, PartInspect L uses advanced automation expertise to meet increased demand for high-speed, high-quality part measurement and analysis.

Hexagon's Manufacturing Intelligence division announced the worldwide launch of PartInspect L, the first automated 3D measurement cell product based on AICON scanner technology. Featuring a choice of structured-light scanning technology paired with a flexible robot arm and housed within a modular cell format, PartInspect L uses advanced automation expertise to meet increased demand for high-speed, high-quality part measurement and analysis.

The system features interactive automated scan planning, as well as robot path generation and collision avoidance systems based on CAD data that deliver a truly automated 3D measurement experience, from planning and scanning through to analysis and reporting.

"This new measurement cell format for our AICON scanner technology makes their high-speed measurement capabilities more efficient and easier to deploy," says Dr. Dirk Rieke-Zapp, commercial product manager for AICON Scanners and Automation at Hexagon. "With PartInspect L, high-speed quality control can be moved into the production space without the need for advanced training for all shop-floor users, offering significant productivity enhancement."

Preassembled and configured in the factory, PartInspect L delivers 'plug-and-play' functionality that allows for set-up within less than two working days and requires no engineering work onsite. The cell will deliver full and fast 3D inspection results for parts measuring up 1.5 meters in diameter/height and weighing up to 2000 kilograms. PartInspect L can be used either offline, near-line or at-line to deliver full or statistical quality control as required.

The system is available in two configurations – Efficient or HiEnd – making use of the several options within the AICON Scanner range. The Efficient configuration features the entry-level AICON PrimeScan, while the HiEnd configuration features the top-of-the-range AICON StereoScan neo. Both configurations can be augmented with the DPA Online photogrammetry add-on for increased measurement accuracy and control.