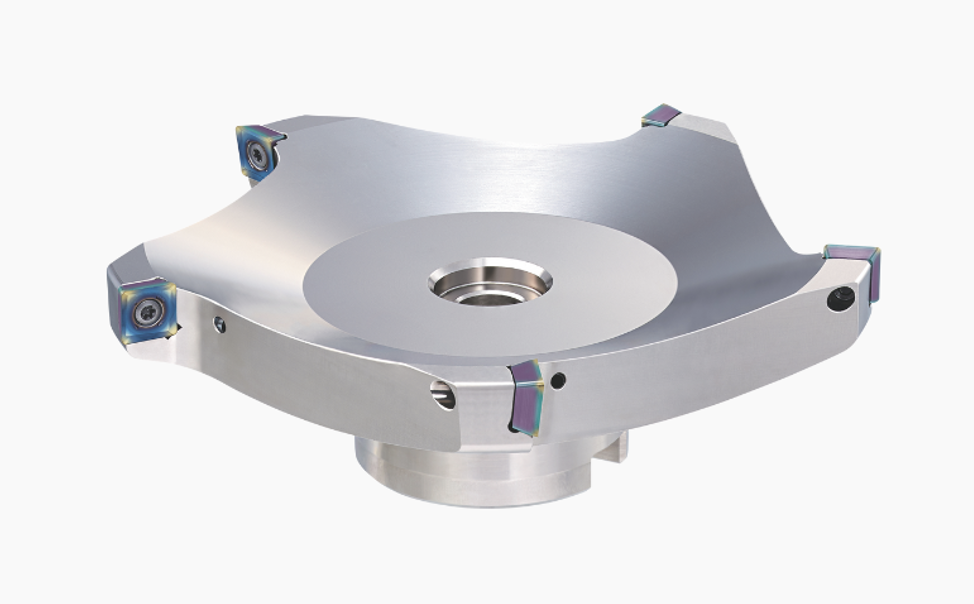

PHOENIX PFDC indexable facemill cutter and inserts

PHOENIX PFDC indexable facemill cutter and inserts

OSG USA Inc., St. Charles, Illinois, releases the PHOENIX PFDC indexable facemill cutter and inserts, designed for non-ferrous materials. This exchangeable facemill cutter is perfect for small machining centers.

OSG USA Inc., St. Charles, Illinois, releases the PHOENIX PFDC indexable facemill cutter and inserts, designed for non-ferrous materials. This exchangeable facemill cutter is perfect for small machining centers.

The cutter series, which includes PFDC 52902, 78351 and 78PSF, features:

- a thin steel body that is lightweight while maintaining high tool rigidity,

- internal coolant channels to improve chip evacuation,

- a breaker shape with a sharp cutting edge ideal for machining non-ferrous materials,

- and compatibility with BT30, ensuring total weight under 3 kg for easy tool management.

View the OSG PHOENIX PFDC product flyer for more information.