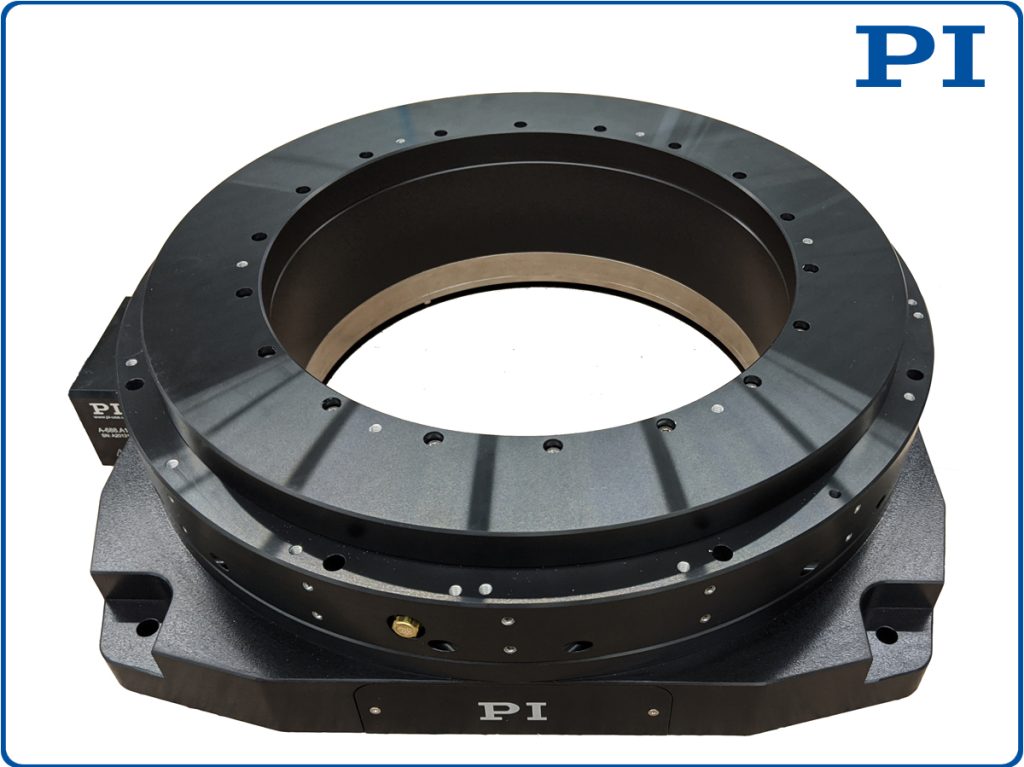

PIglide A-688 Rotary Air Bearing

PIglide A-688 Rotary Air Bearing

Air-bearings have no rolling or sliding elements and deliver frictionless, non-contact motion, resulting in negligible reversal error, better flatness, and minimal wobble and eccentricity. All these are ideal prerequisites for applications such as inspection and metrology, calibration, and scanning of high-end parts (i.e., infrared and precision optics, turbine blades, shafts and bearings) in industries like aerospace, aircraft, automotive, semiconductors, and photonics.n

PI (Physik Instrumente), a leader in precision motion control and nanopositioning solutions, announces a new large motorized rotary air bearing added to its existing families of PIglide air bearing rotary stages.

Why Air Bearings

Air-bearings have no rolling or sliding elements and deliver frictionless, non-contact motion, resulting in negligible reversal error, better flatness, and minimal wobble and eccentricity. All these are ideal prerequisites for applications such as inspection and metrology, calibration, and scanning of high-end parts (i.e., infrared and precision optics, turbine blades, shafts and bearings) in industries like aerospace, aircraft, automotive, semiconductors, and photonics.

Nanopositioning in Any Aspect

Air bearings replace mechanical contact by a thin film of air which is completely frictionless, resulting in no breakaway stiction or drag friction during operation. Featuring high performance, low-cogging frameless slotless torque motors and optical encoders, these stages can be used in any orientation. The A-688 is customizable with options to create a solution for point-to-point indexing or constant velocity scanning. Coupled with no required maintenance or lubrication, these rotary positioners have a virtually unlimited life.

Features & Advantages

- ⌀260mm clear aperture

- 77kg load capacity

- 0.0015µrad max. resolution

- 500 RPM max.

- Flatness/Eccentricity <175/300nm

- Wobble: < 1µrad

- Direct drive

Substantial Design and Manufacturing Experience, Standard and Custom Systems

PI designs and manufactures all air bearing products in the USA. PI's engineering team has hundreds of man years of air bearing design and manufacturing experience. In addition to customized systems for OEMs, PI offers a substantial standard product line of air bearing stages that includes motorized and non-motorized, linear, rotary, spherical, X/XY, voice coil, compact, and large scale systems, as a complement to its existing comprehensive range of piezo nano positioning stages, traditional motorized positioners, and hexapod 6-axis parallel positioning systems. The extreme depth and breadth of motion technologies puts PI in the unique position to cover the whole motion range from finger-tip sized nano-positioners to large scale stages with long travel ranges, through a plethora of different drives and guiding systems that can be tailored to meet the needs of an OEM or customer.