Pitch Adjustment Option for Uhing RG Linear Drives

Pitch Adjustment Option for Uhing RG Linear Drives

Amacoil/Uhing has introduced a new option for Uhing RG linear drives which enables extremely fine adjustment to the linear pitch of the drive unit.

Amacoil/Uhing has introduced a new option for Uhing RG linear drives which enables extremely fine adjustment to the linear pitch of the drive unit. Using the new control knob option, the pitch may be adjusted while the drive is moving without changing motor speed. Nor is there any need for gear reduction. The pitch adjustment option enhances both positioning accuracy of the drive unit and control over linear speed in linear motion applications.

The standard linear pitch adjustment control on the Uhing RG drive is a lever which is manually moved to a notched setting on a scale. Each notch increases or decreases pitch by 0.01. There are 100 discrete notched settings on the scale which enable a 10:1 turndown of the linear pitch of the drive unit. For example, if the drive is set up with a maximum pitch of 0.25 inches, the operator may use the pitch control lever to turn down the pitch to 0.02 inches.

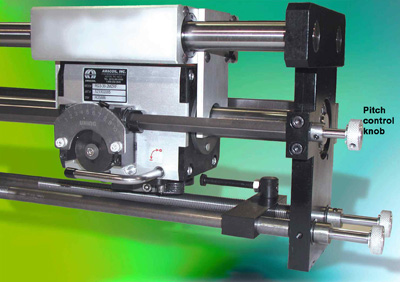

The new pitch control option bypasses the notched settings on the scale by using a worm gear and threaded rod design. To change linear pitch, the operator turns a control knob on the end of the threaded rod. This may be done safely while the drive is operating, so there is no need to stop the system or adjust any other controls. A pitch indicator moves along the scale as the control knob is turned.

Whereas the standard control lever limits pitch adjustability to the notched settings on the scale, the worm gear option permits virtually infinitely adjustable pitch throughout the 10:1 adjustable pitch range. This fine tuning capability means the operator has more accurate control over the drive unit's linear position along the travel path.

Simply turning the control knob increases or decreases the linear pitch of a Uhing drive unit which effectively changes the linear speed of the drive. The mechanism is purely mechanical, intrinsic in the design of the Uhing drive. This affords both operators and designers a variable speed linear drive system that does not require clutches, cams or gears. Once the linear pitch is set on a Uhing drive, it remains constant, regardless of the drive motor speed or other control settings. The new pitch control option may also be retrofitted to existing Uhing linear drive set ups.