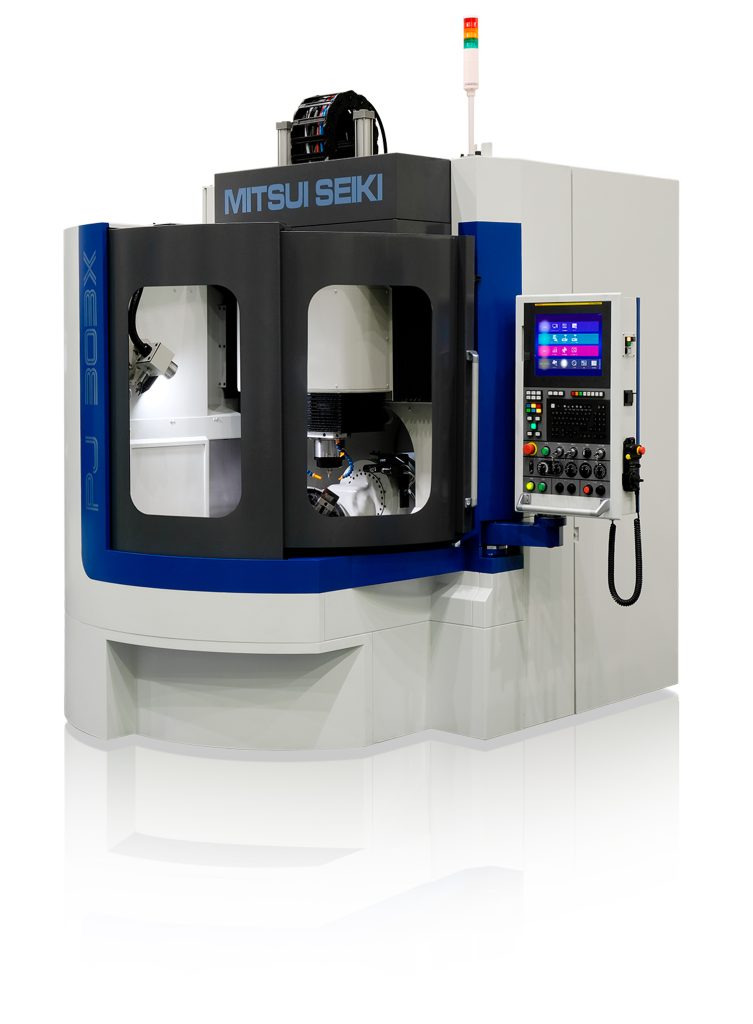

PJ 303X 5-Axis Machining Center

PJ 303X 5-Axis Machining Center

The machine's X-, Y-, and Z-axis travels are 300mm, 325mm, and 200 mm (11.8", 12.8", 7.9") respectively. A-axis rotation is +40˚ to -100˚, and the C-axis rotates a full 360˚. High-speed linear motors move the X-, Y- and Z-axes, while the rotary axes employ direct-drive motors. Rapid traverse speed for the X-, Y-, and Z-axes is 20 m/min (66 ft/min).

Mitsui Seiki's new PJ 303X 5-axis machining center provides maximum precision and versatility in processing of workpieces up to 230mm tall and 280mm in diameter (9" x 11"), and 20 kg (44 lbs.) in weight. Typical applications cover an extensive range of critical parts such as lens molds, medical products, EDM electrodes and fuel cell components.

The machine's X-, Y-, and Z-axis travels are 300mm, 325mm, and 200 mm (11.8", 12.8", 7.9") respectively. A-axis rotation is +40˚ to -100˚, and the C-axis rotates a full 360˚. High-speed linear motors move the X-, Y- and Z-axes, while the rotary axes employ direct-drive motors. Rapid traverse speed for the X-, Y-, and Z-axes is 20 m/min (66 ft/min).

A 50,000-rpm, HSK-E25 taper spindle offers high-speed machining capability. An automatic tool changer engineered to store up to 24 tools as large as 40mm (1.57") in diameter and 120mm (4.7") in length provides tooling versatility.

To maximize precision, the sliding machine surfaces of the PJ 303X are hand-scraped.

Advanced spindle thermal displacement technology is standard, including a symmetrical gantry column structure that accommodates thermal deformation fluctuations and a thermal compensation mechanism for the machine spindle/head.

Operator-friendly features further enhance precision, including a 380mm (15") color display with touch panel capability than can be moved to the most convenient position relative to the work envelope. The machine's double-stage rotary door provides wide access for visibility and setup.

The PJ 303X consumes a compact 1,755 mm (5.75') x 2,370mm (7.77') x 2,655 (8.7')

(W x L x H) of floor space, and weighs approximately 4,500 kg (9,900 lbs)

Mitsui Seiki USA chief operating officer Bill Malanche said, "The compact PJ 303X machining center provides high precision, speed and versatility for the processing of an important range of part sizes across a wide variety of applications."