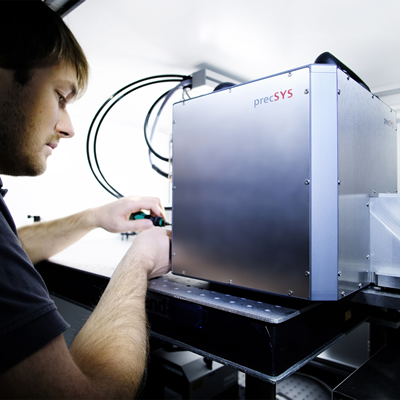

precSYS Micromachining System

precSYS Micromachining System

SCANLAB GmbH's precSYS micromachining system is drawing positive responses from integrators and system builders. The system's individualized customer service, with in-person commissioning guidance, training and on-site application support, has proven to be of practical advantage. Customers who build laser processing systems to fabricate products, such as electronic devices or automotive components, achieve good processing results much more quickly, thus boosting their productivity.

SCANLAB GmbH's precSYS micromachining system is drawing positive responses from integrators and system builders. The system's individualized customer service, with in-person commissioning guidance, training and on-site application support, has proven to be of practical advantage. Customers who build laser processing systems to fabricate products, such as electronic devices or automotive components, achieve good processing results much more quickly, thus boosting their productivity.

The robust precSYS 5-axis scan system was created for industrial volume production via ultra-short-pulse (USP) laser micromachining. The system enables fabrication of flexibly definable geometries, e.g. bore holes that are positively or negatively conical, ideally cylindrical, circular, rectangular or elliptical, as well as cavities with high aspect ratios and all with very good quality entrance and exit edges. Moreover, it's equipped with an integrated controller, an embedded PC and a user-friendly graphical interface (GUI). The 3D software allows users to visualize and precisely plan their laser jobs in advance, thereby avoiding mistakes.

Particularly welcome are the ultraprecise factory precalibration, default alignment software features, alignment aids and optional sensor-based automatic fine adjustment. This fine adjustment option enables automatic beam-position checking and correction in less than a minute, to ensure accurate positioning within the image field and long-term stability during processing.

With its in-person commissioning guidance, the system's on-site customer service includes a professional acceptance procedure to ensure that the delivered system exactly fulfills its specifications. Moreover, this support makes sure that the micromachining subsystem works optimally and stably in conjunction with the customer's specific lasers. Thus, very good results are quickly achievable even in the initial test phase.