Contact Details

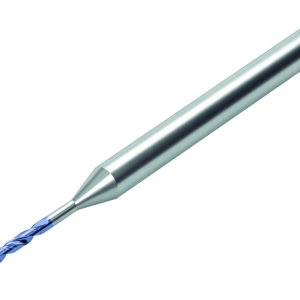

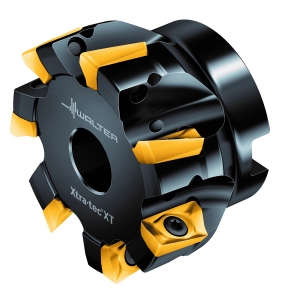

Walter has introduced its new Prototyp Advance line of solid-carbide milling tools for universal application. The new Advance milling cutter line consisting of six cutter types and 250 line items, each reportedly providing the ideal balance of hardness and toughness for the widest possible application, plus long tool life (increases of up to 50 percent) thanks to the Advance line’s new high-performance WJ30TF grade and Walter’s TiAIN coating.

Walter’s Advance line tools are well suited to machining an array of materials (ISO material groups P, M, K and S) and can help reduce inventory costs as well.

The cost-effective Advance line features standard geometries of 30° and 45° helix angles and comes in two main tool configurations, the shoulder mill and the shoulder/slot mill. The universal shoulder mill category consists of the MC111 milling cutter with a 30° helix angle and four cutting edges; the MC112 30° with four cutting edges; and the MC122 45° with four to eight cutting edges.

The Advance shoulder/slot mill category consists of the MC213 30° with two to four cutting edges; the MC216 30° with two or three cutting edges; and the MC322 45° with four cutting edges.

Related Glossary Terms

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- hardness

hardness

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

- helix angle

helix angle

Angle that the tool’s leading edge makes with the plane of its centerline.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

PRODUCTS

PRODUCTS