Contact Details

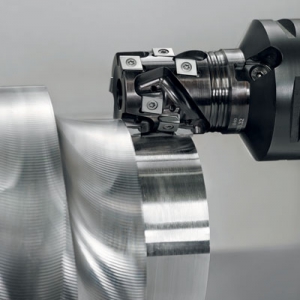

The new PVD-coated WHH15X milling grade from Walter excels at finishing and semi-finishing of hardened components up to 63 HRC as well as finish-milling of steel and cast-iron components when using wiper inserts. Finish machining of a component is possible with just one cutting edge.

The grade can also provide extra-long tool life, especially with hardness of 58 HRC or greater. The new WHH15X grade can be used universally for finishing on ISO materials P, K, and H, and is ideal for copy milling in die and mold making. It provides the high surface quality thanks to its wear resistance and edge stability, and yields cost savings by reducing the need for manual rework when copy forming.

The WHH15X grade features HIPIMS technology for excellent coating adhesion and a high degree of hardness, and AlTiN coating optimized for hard machining; this results in an extremely smooth surface for the best chip removal and high surface quality. This new grade also has an extremely wear-resistant carbide substrate and is available for tools for copy milling and finish milling, such as: the F2234 and F2231 round insert milling cutters, the F2139 profile milling cutter, the M5008 high feed milling cutter, as well as the SDHX, BCGX, and LNHX wiper inserts.

Related Glossary Terms

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- hardness

hardness

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.

PRODUCTS

PRODUCTS