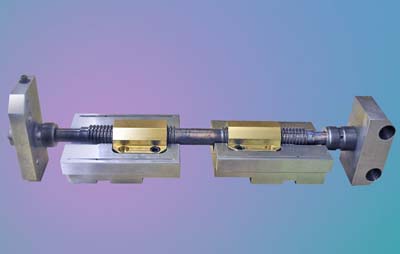

Quad Vertical Chuck Fixture

Quad Vertical Chuck Fixture

Royal Machine & Tool Corp. has introduced a newly designed QVC (quad vertical chuck fixture) for horizontal machining centers.

Royal Machine & Tool Corp. has introduced a newly designed QVC (quad vertical chuck fixture) for horizontal machining centers, featuring a patent pending clamping screw cartridge, which reportedly provides greater gripping forces and ease of maintenance. In announcing the newly designed QVC, Bernie McAloon, Sales Manager, stated, "Older designed QVC's required the replacement of the master jaw and the adjusting screw when thread damage occurred. With the new design, simply unfastening the old, damaged cartridge and fastening in a new cartridge allows repair in the field and quickly returns the fixture to service. Thus, eliminating the possible downtime and costly expense of rebuilding." The new clamping screw cartridge is also available on Royal's independent adjustable jaw chucks. The new QVC is designed with American Standard Tongue and Groove Master Jaws and is available in 400mm and 500mm sizes. The new design permits using existing top-tooling and off-the-shelf standard blank jaws. Mounting features also can be supplied to the customer's specific requirements. Royal QVC's hold up to 8 parts and permit virtual continuous spindle use, decreased tool changes and practically eliminate downtime for parts changeovers, according to the company.