Quick Image CNC (QI-C) 2D Vision Measurement System

Quick Image CNC (QI-C) 2D Vision Measurement System

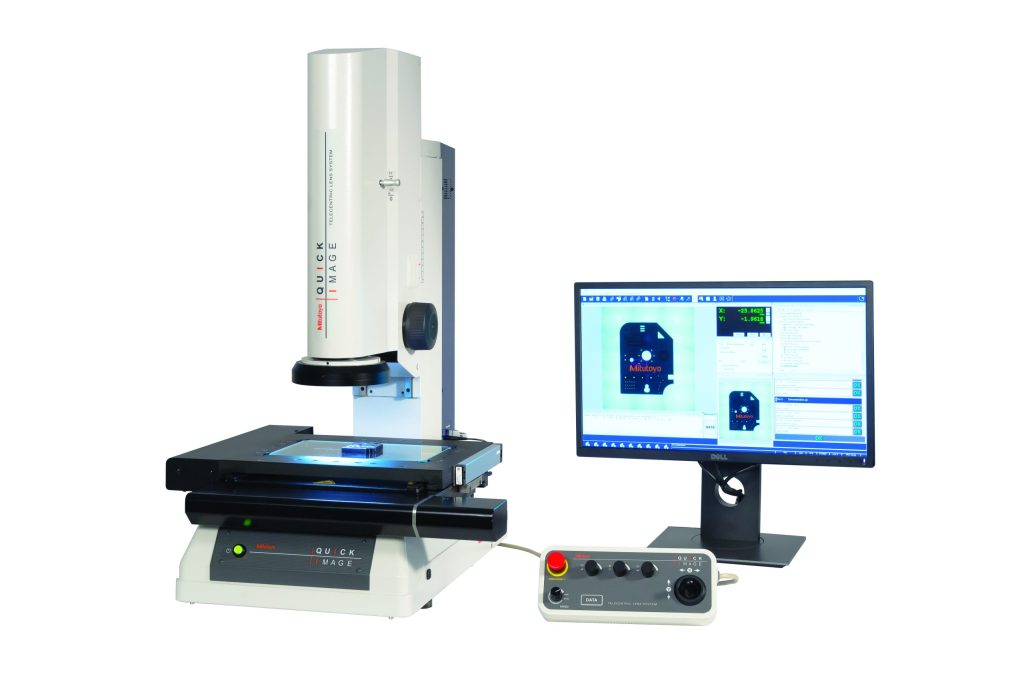

Mitutoyo America Corp. announces the release of the Quick Image CNC (QI-C), the latest addition in the Quick Image series of 2D vision measuring systems. The Quick Image series of telecentric lens-based 2D video inspection systems has expanded the lineup to include three new models with a moving stage.

Mitutoyo America Corp. announces the release of the Quick Image CNC (QI-C), the latest addition in the Quick Image series of 2D vision measuring systems. The Quick Image series of telecentric lens-based 2D video inspection systems has expanded the lineup to include three new models with a moving stage.

Combined with the moving stage, the QIPAK software now includes an image stitching function. The small footprint and ergonomic design are well-suited for a variety of inspection tasks, both in the lab and on the shop floor.

For larger workpieces, the combination of the moving stage and image stitching allows for entire coverage of the measuring envelope, creating a single stitched image on which edge detection can be applied. QIPAK software creates inspection routines, part programs and repeat measurements using a single mouse click. The telecentric all-in-focus optics is suited for shafts, stampings, plastics, electronics and other difficult-to-focus workpieces.

The QI-C Series features a wide field of view (32 x 24 mm), depth of focus (up to ±11mm), fully motorized X-Y stage and the latest QIPAK software, providing the user with automated measurements throughout the range of stage travel. The telecentric optical system, combined with the image stitching capability of QIPAK V6.1, allows fully automated wide-area measurements. The QI-C Series is available with 0.2X optical magnification, measuring accuracy of (3.5 + 0.2L)µm, and measuring range options of 200mm x 100mm, 200mm x 170mm and 300mm x170mm.

Measurement results are displayed in real time directly on the video image, enabling tolerance judgments at a glance. With improved measurement accuracy, Quick Image ensures class-leading quality and capability. High-luminance with the built-in LED lighting, and megapixel color camera enable observation and measurement using high-resolution images.