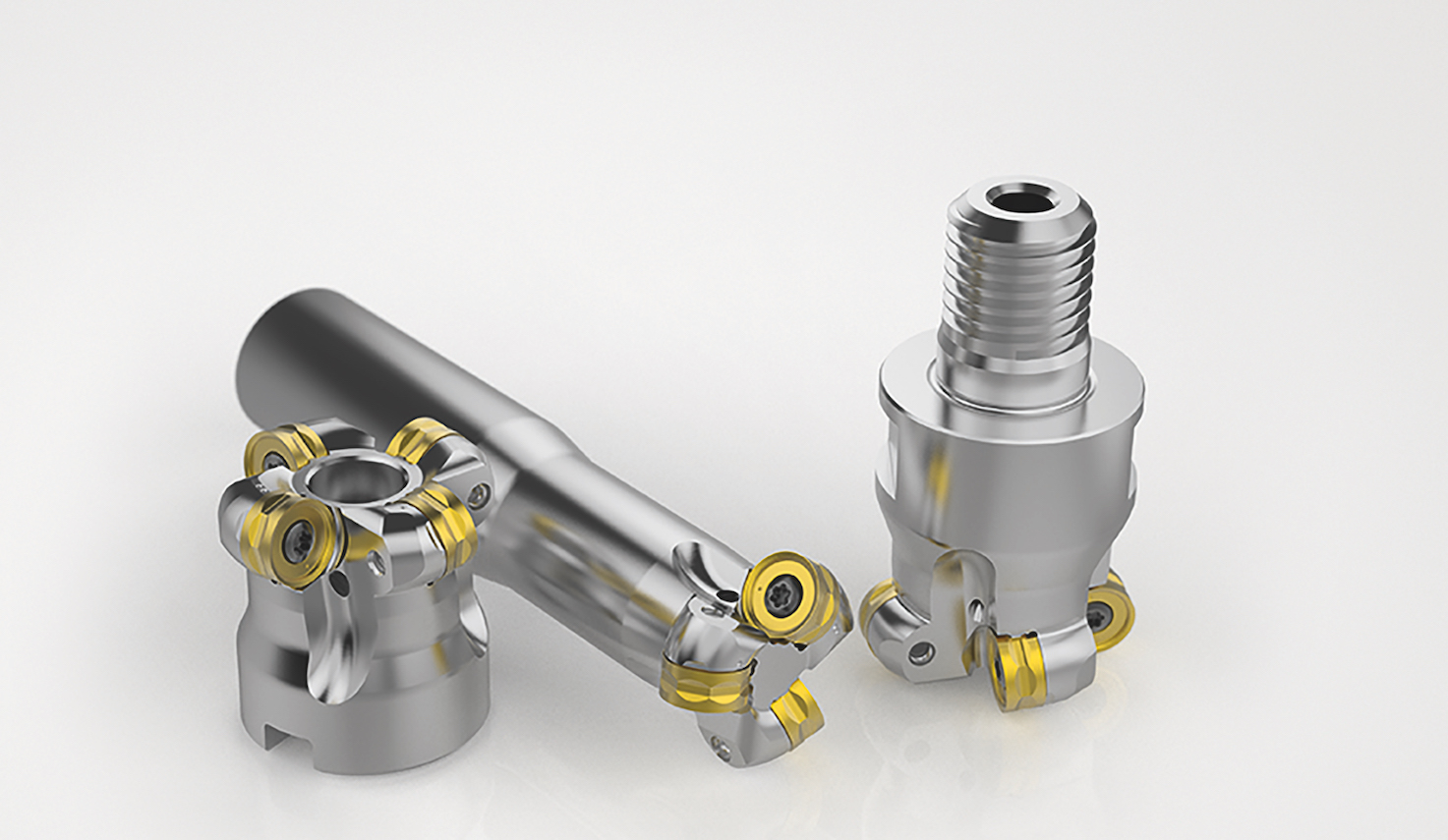

R217/220.28 Milling Cutters

R217/220.28 Milling Cutters

Seco Tools has introduced its R217/220.28 cutters with new body designs that incorporate double-sided round inserts to deliver cost-effective performance, as well as boost productivity. Double-negative-positioning pocket seats of the R217/R220.28 cutters deliver enhanced cutting capability and significant gains in productivity, according to the company.

Seco Tools has introduced its R217/220.28 cutters with new body designs that incorporate double-sided round inserts to deliver cost-effective performance, as well as boost productivity. Double-negative-positioning pocket seats of the R217/R220.28 cutters deliver enhanced cutting capability and significant gains in productivity, according to the company. These pocket seats also enable safe and user-friendly indexing to save time and provide trouble-free operation.

The R217/R220.28 performs facemilling, slotting and contouring in ISO M and ISO S materials, as well as some difficult-to-machine ISO P materials, such as martensitic stainless steel. The cutter excels in Z-leveling applications and is ideal for machining turbine blades for the aerospace and power generation segments.

The range for R217/220.28 includes diameters from 1.25" (32mm) to 4.00" (100mm) in normal and close pitch versions. The 12mm IC inserts are available in PVD and CVD grades with two different geometries for varying applications.