Radan 2018 R1 Software

Radan 2018 R1 Software

Radan 2018 R1 is a major step forward with technology geared to help sheet-metal manufacturers implement Industry 4.0 smart factories, and is the first of two 2018 releases in step with plans to begin issuing two new versions per year.

Radan 2018 R1 is a major step forward with technology geared to help sheet-metal manufacturers implement Industry 4.0 smart factories, and is the first of two 2018 releases in step with plans to begin issuing two new versions per year.

"We're aiming to get the very latest developments to customers as quickly as possible," said Radan Product Manager Olaf Körner. "Starting with Radan 2018 R1, customers needn't ever be working with software that is more than six months old."

The new release includes a number of items of new and enhanced functionality that focuses specifically on the "engineering of parts" processes. Developers are now working on separating Radan into two distinct aspects: traditionally creating NC code to drive CNC machines, and "engineering of parts."

"Radan isn't just a CAM system any more. It plays an important role in ensuring sheet-metal manufacturers are best placed to run with Industry 4.0," Körner said. An example of this is with Radmanager. The system now accepts feedback from the shop floor regarding cutting progress. "This improved connection between the shop floor and logistics operations means the stock management and order processing functions can immediately update the stock control."

Radquote now looks at all aspects that impact how much it costs to bend a part, such as how many bends are required, how many turns or flips the operation needs, and whether it needs a second operator, to provide an accurate cost calculation. In addition, it calculates the cost of an entire 3D assembly, rather than individual parts. "The user can see a full assembly, and the total cost.

"These bending cost calculations – both for individual parts and complete assemblies – and the finegrain information flow between the shopfloor and Radmanager will assist considerably in facilitating the next generation of sheet-metal production as part of a connected factory infrastructure," Körner said.

Moving on to enhanced CAD/CAM functions, Radan 2018 R1 takes the increasing popularity in automatic bending into consideration, with the specific innovation of optimizing fingerstops. As part of a process of making fingerstops safer, it allows for improved part alignment in the press brake and reduces the number of fingerstop movements required between bends.

In addition, an enhancement to the default views means designers can bring up a front view, side view, or isometric view instantly, in both Radbend and Radan 3D.

The profiling function benefits from six updates. For hatching, laser users can now create fine marks to identify parts. Körner says these marks can be of any shape, such as a barcode design, text, or a number, and is simply "hatched" on to the metal with the laser.

Enhanced flycutting, where the machine doesn't stop during an entire operation, reduces cycle times; the lead-in placement for tagging has been optimized. Additional support for automatic filleting means users have much greater control over where they are placed, as they can be switched on for one part and off for another, and whether they are on internal or external corners.

Radan developers have worked closely with plasma-cutter manufacturers on additional support for cutting circular holes with higher accuracy on plasma CNC machines. Following the contours of a part when creating offcuts saves more of the material, reducing waste even further.

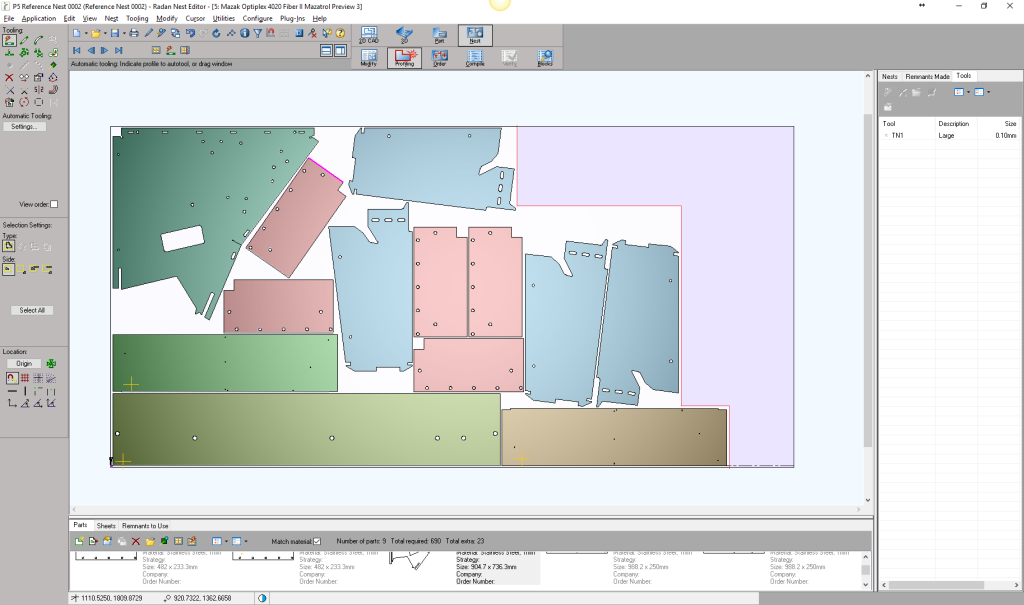

A new batch-nesting system is described as a "big performance upgrade," which forecasts show could improve material usage by around 9 percent over a year. A new algorithm provides a different approach to optimizing a range of nests. "The software now looks at the entire nest run and reduces the number of overall sheets instead of focusing on how full each individual sheet is," Körner said.

New controls have been added for producing offcuts on punch presses. "Some manufacturers like offcuts at the start of a program; others prefer them at the end. This enhancement means they can decide exactly when the offcut parts will be created," Körner said.

Finally, five individual enhancements combine to improve Radan's overall CAD/CAM usability:

- Radan 2018 R1 includes a more natural way of maneuvering around the parts to select features.

- One click to update the stock list in nest projects

- Improvements to the process of changing programs from one machine tool to another, whether switching between cutting technologies, or laser to laser but powered by a different gas. "It's now easier to create a CNC program for one machine, and then for a different machine using a different post processor."

- The Teamviewer system, which support engineers use to gain remote access to a customer's system for resolving issues, is built into the latest software release.

The optional Analytics system helps Radan developers gather evidence regarding how customers use the software, so that each new release can focus on the industry's requirements. "For example, it shows us which functions are used the most, and the sequence of clicks, which means we can look at optimizing that in the future. It provides a tangible indication of where we should be looking to make enhancements, and is part of our ongoing philosophy of ensuring that the software is absolutely right for the customer, enabling them to take their businesses to the next level," Körner said.