REV Motorized Slotter

REV Motorized Slotter

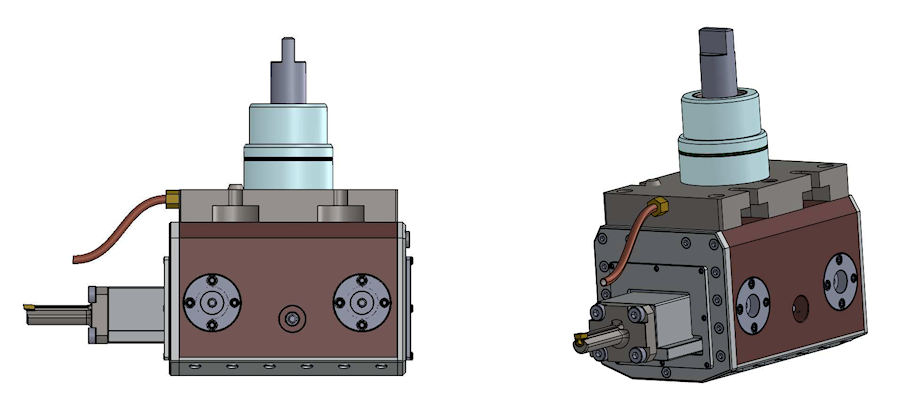

The REV motorized slotter is designed to solve, in the most efficient way, the problem of having to perform certain processing operations on a CNC lathe, from a simple keyway to internal or external toothed profiles.

The REV motorized slotter is designed to solve, in the most efficient way, the problem of having to perform certain processing operations on a CNC lathe, from a simple keyway to internal or external toothed profiles.

The REV motorized slotter is designed to obtain maximum rigidity. This feature allows the insert to be used for a long time and the processed surface to have an excellent degree of finish.

There are remarkable advantages in using this slotter: in addition to its extremely fast processing speed, the piece does not need to be moved on other machines, thus avoiding further tool set-ups.

The REV motorised slotter has several adjustments, which are useful for achieving correct processing, and can perform internal or external processing.

The REV motorised slotter is protected by patent.

Advantages:

• Y- and Z-axis correction (patent protected aspect);

• Extreme rigidity, a characteristic that ensures an excellent degree of finish and, at the same time, a long life of the cutting edge of the insert; and

• Time saving, allowing to carry out the work in extremely fast times and avoiding, at the same time, the movement of the piece and the use of additional machine tools.