RPA Flame Kool Synthetic Metalworking Fluid

RPA Flame Kool Synthetic Metalworking Fluid

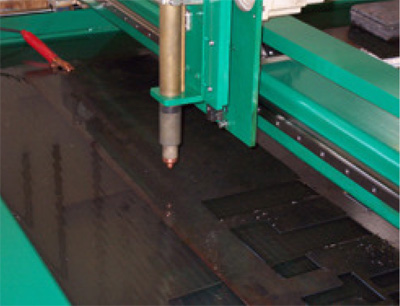

RPA Flame Kool from Chemtool Inc. is a moderate-duty, synthetic metalworking fluid formulated for general utilization on plasma cutting tables.

RPA Flame Kool from Chemtool Inc. is a moderate-duty, synthetic metalworking fluid formulated for general utilization on plasma cutting tables. RPA Flame Kool provides an optimal balance of cooling, wetting-detergency, corrosion protection and workpiece visibility for plasma cutting table operations for ferrous alloys only, according to the company.

RPA Flame Kool exhibits enhanced wetting and coverage properties for plasma cutting table applications where critical fluid film strength properties are required. A balanced corrosion inhibitor blend offers excellent protection against corrosion and staining of gray iron, cast iron, and ferrous alloys and for freshly cut ferrous surfaces. RPA Flame Kool is stable in a variety of process water chemistries.

RPA Flame Kool does not deposit a sticky or tacky residue on machine or cut surfaces. The residue is very fluid-like and will not gum up ways or stick switches. RPA Flame Kool readily rejects most process oil contaminants which may be easily removed with standard skimmers and other removal systems. RPA Flame Kool is formulated with additional reserve alkalinity for prolonged fluid performance and contains no formaldehyde releasing chemistries. RPA Flame Kool can also be utilized as a leak detection or nondestructive test fluid for ferrous metals or ferrous alloy assemblies.

Product benefits include:

True solution chemistry and low foaming properties assure clean clear work piece visibility.

Imperceptible thin film corrosion preventative provides excellent tack free in-process rust protection.

Good hard water stability keeps table surfaces clean and substrates free from buildup.

Exceptional wetting and coverage properties for good performance on ferrous substrates and complex geometries.

Oil rejecting properties keeps the sump clean and free of odor from microbiological contamination.

Additional reserve alkalinity for prolonged sump life.

Contains no triazine or formaldehyde releasers.