RT 100 S Drill

RT 100 S Drill

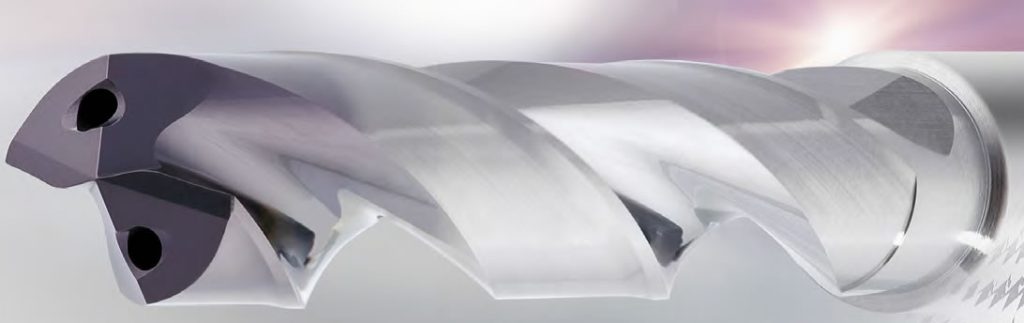

The RT 100 S drill from Guhring was especially developed for the complex machining of steel materials. It reportedly scores points thanks to high cutting values and consistently good hole quality. An especially stable and accurate cutting edge is produced thanks to the special micro-geometry.

The RT 100 S drill from Guhring was especially developed for the complex machining of steel materials. It reportedly scores points thanks to high cutting values and consistently good hole quality. An especially stable and accurate cutting edge is produced thanks to the special micro-geometry.

The extremely smooth surface finish of the RT 100 S web thinning and flute profile reduces the friction between drill and chip. The machining temperature is reduced and chip evacuation improved. Cutting forces are reduced. These tool features result in maximum hole quality and tool life, according to the company,

Application include:

structural and free-cutting steels

alloyed and unalloyed heat-treatable steels

alloyed and unalloyed case hardened steels

tool steels and high speed steels