AS Series of Grinding Steady Rests

AS Series of Grinding Steady Rests

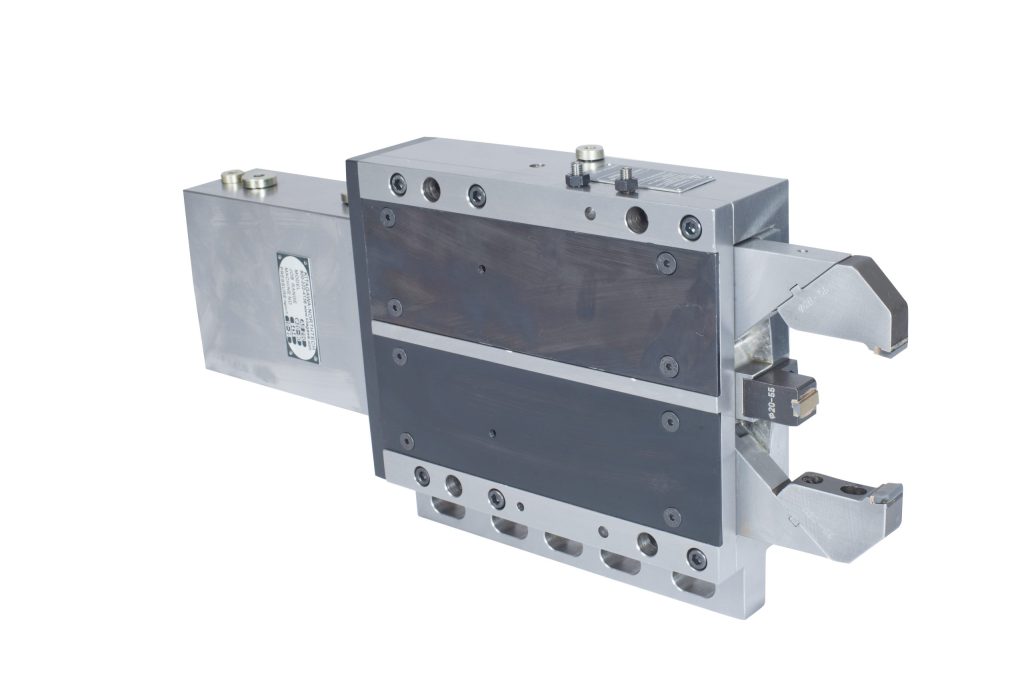

Kitagawa NorthTech Inc. introduces its new AS series of grinding steady rests. The AS series expands and completes the company's portfolio of steady rests specifically designed and engineered for grinding applications. The new AS steady rests feature narrow retractable arms for easy automated part loading, as well as many other capabilities for grinding applications.

Kitagawa NorthTech Inc. introduces its new AS series of grinding steady rests. The AS series expands and completes the company's portfolio of steady rests specifically designed and engineered for grinding applications. The new AS steady rests feature narrow retractable arms for easy automated part loading, as well as many other capabilities for grinding applications.

The narrow retractable arms prevent interference with oil hole journals and provide easy vertical loading of the work piece. Available in standard gripping diameters from 0.39" (10 mm) to 5.59" (142 mm) range, the AS series steady rests can accommodate eccentric throw with body modifications for crank lobe clearance.

Key features and benefits include:

• Steady rest with retractable arms for easy overhead gantry/robot loading

• Suitable for all crankshaft, camshaft and cylindrical grinding applications where vertical load is a requirement

• High accuracy, with three-point finely adjustable centering capability

• Modular regrindable carbide or relappable PCD work rest pads

• Suitable for pass-through grinding capabilities

• Provisions to accommodate attenuating in-process gaging (IPG)

Earlier this year Kitagawa NorthTech launched the new grinding series with the KRGU and GHS. The retracting KRGU grinding steady rests and GHS/VGHS grinding steady rests designed for camshafts, crankshafts and other cylindrical applications. The KRGU is specially designed for crankshaft grinding to accommodate the maximum eccentric throw and journal diameter of crankshafts. The GHS is suitable for all crankshaft, camshaft and cylindrical grinding applications where vertical load is a requirement.