SIGC Small Internal Grooving Tool

SIGC Small Internal Grooving Tool

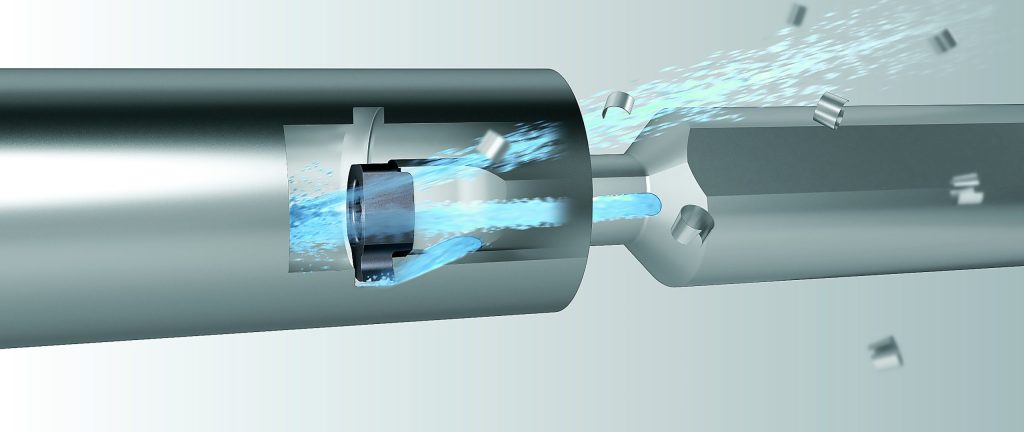

Kyocera Precision Tools introduces the new SIGC small internal grooving tool. The SIGC toolholder has a newly developed clamping system providing a firm insert hold made for the most efficient high-precision machining.

Kyocera Precision Tools introduces the new SIGC small internal grooving tool. The SIGC toolholder has a newly developed clamping system providing a firm insert hold made for the most efficient high-precision machining.

Double coolant holes provide additional wear resistance while the optimized flute shape effortlessly removes chips from the cutting edge. With a minimum bore diameter of 8mm, the SIGC is highly suitable for small internal grooving applications.