Contact Details

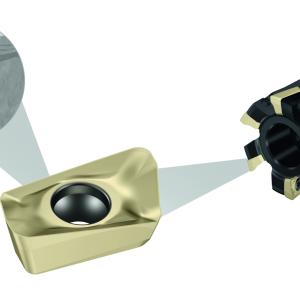

Walter USA LLC has introduced the new TigerÌ¢è ‰ã¢tec Silver Turning for steel turning applications. Consisting of three new grades and four new geometries, this product line can bring longer tool life, faster cycle times and process reliability to a wide array of applications. The TigerÌ¢è ‰ã¢tec Silver Turning can handle a variety of materials including unalloyed and alloy steel, cast steel, stainless ferritic and martensitic steel, as well as ductile cast iron.

Key to this success is the proven Tiger-tec Silver CVD coating. When combined with the newly developed insert geometries and universal chipbreakers, it can increase steel turning productivity up to 75 percent. The substrate for these indexable inserts is a new, micro-structured aluminium oxide. Thanks to its specially oriented crystalline structure, it can also raise tool life in the event of crater wear by 50 percent, which significantly reduces machining time.

In addition, an optimized cutting edge preparation process called Microedge Technology reduces cracks, micro-chipping and breakage, boosting process reliability in high volume production. Microedge Technology can also increase tool life by 30 percent by reducing flank face wear and plastic deformation of the insert. Process reliability is heightened when making interrupted cuts as well, thanks to optimum seating of the new inserts in the toolholder. The inserts&' silver flank faces also serve as an indicator layer for easy wear detection.

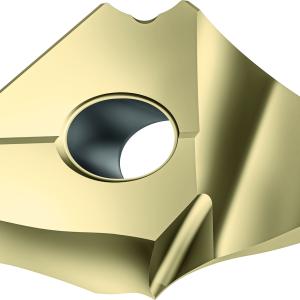

The new generation of indexable inserts for steel turning consists of three grades: WPP10S (ISO P10), WPP20S (ISO P20) and WPP30S (ISO P30). The WPP10S grade (ISO P10) offers the highest temperature resistance and hardness and provides excellent wear resistance and is suitable for applications ranging from continuous cutting up to slightly interrupted cuts. The WPP20S (ISO P20) is a universal grade for applications ranging from roughing to finishing. The WPP30S (ISO P30) grade was developed for tough cutting conditions.

Alongside these three grades, four previously introduced geometries have been developed in parallel within the TigerÌ¢è ‰ã¢tec Silver Turning family: FP5, MP3, MP5 and RP5.

Related Glossary Terms

- chemical vapor deposition ( CVD)

chemical vapor deposition ( CVD)

High-temperature (1,000° C or higher), atmosphere-controlled process in which a chemical reaction is induced for the purpose of depositing a coating 2µm to 12µm thick on a tool’s surface. See coated tools; PVD, physical vapor deposition.

- edge preparation

edge preparation

Conditioning of the cutting edge, such as a honing or chamfering, to make it stronger and less susceptible to chipping. A chamfer is a bevel on the tool’s cutting edge; the angle is measured from the cutting face downward and generally varies from 25° to 45°. Honing is the process of rounding or blunting the cutting edge with abrasives, either manually or mechanically.

- hardness

hardness

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

- parallel

parallel

Strip or block of precision-ground stock used to elevate a workpiece, while keeping it parallel to the worktable, to prevent cutter/table contact.

- plastic deformation

plastic deformation

Permanent (inelastic) distortion of metals under applied stresses that strain the material beyond its elastic limit.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

PRODUCTS

PRODUCTS