SMIRT 2019 R1 Software

SMIRT 2019 R1 Software

SMIRT 2019 R1, the latest release of Vero Software's powerful viewing and manufacturing solution for the die-mold industry, introduces new on-machine inspection functionality and enhanced templating functionality for added process planning automation.

SMIRT 2019 R1, the latest release of Vero Software's powerful viewing and manufacturing solution for the die-mold industry, introduces new on-machine inspection functionality and enhanced templating functionality for added process planning automation.

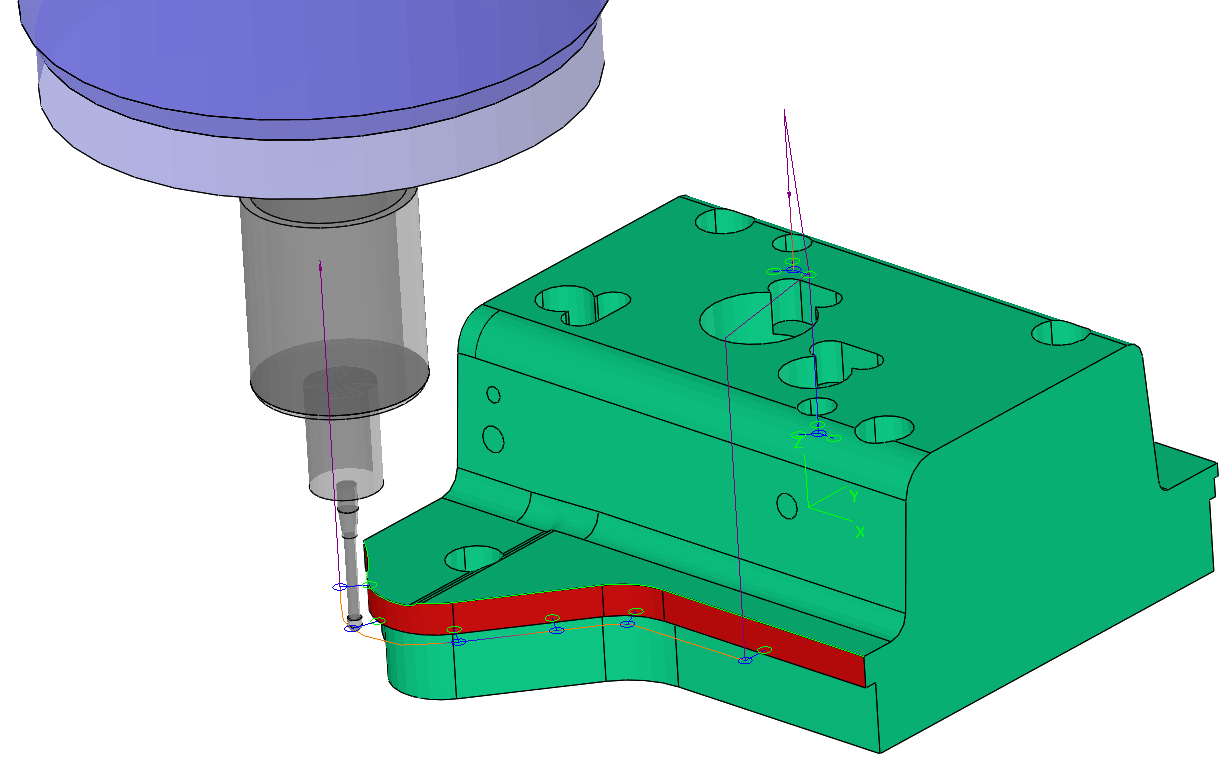

SMIRT Inspect is an all new module for 2019 R1 that allows on-machine part inspection for profile/periphery surfaces. SMIRT Inspect utilizes the measurement capabilities of Hexagon's PC-DMIS, along with the NC Gateway for communication with the machine tool controller. Key features of SMIRT Inspect include:

- Familiar SMIRT user interface

- Automatic creation of inspection touch points based on user settings and profile curvature

- Easy addition and removal of inspection points

- Automatic collision detection as probe path and inspection points are created

- Post-processing simultaneously generates machine tool commands and inspection feature data for PC-DMIS

- Automatic generation of text-based report with inspection results

Building upon the improvements of SMIRT DieBuild and DbTemplateUtil released in 2017, functionality has been added to allow planners to automatically collect task surfaces based upon the description of the items mounted to it. This alleviates the need for design files to contain special feature attributes to differentiate surfaces that may share the same color, direction or machining attribute.

"This new functionality will make using Process Templates more efficient to more of our customers, who may not have specially attributed designs to work with," says SMIRT Product Manager Ben Postiff.

SMIRT Brand Manager Miguel Johann says, "The product's process planning, process tracking and shop-floor execution capabilities make it a unique solution within Hexagon's production software portfolio. We have exciting plans for the brand and the product, with our customers' needs at the core of them."