Software Suite with CUBE-R 3D Automated Dimensional Inspection Solution

Software Suite with CUBE-R 3D Automated Dimensional Inspection Solution

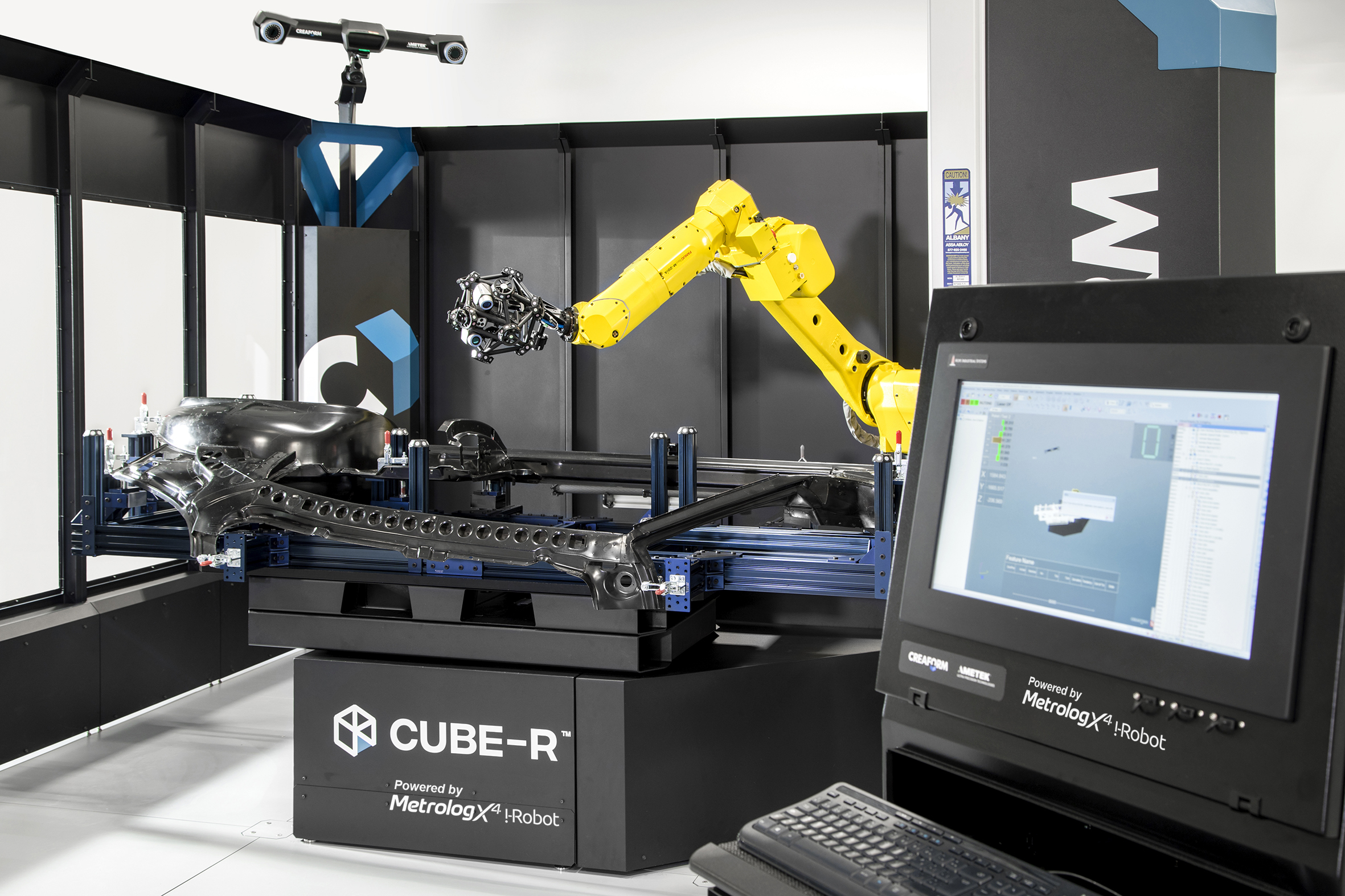

Metrologic Group and Creaform have entered into a partnership in which Creaform integrates Metrologic Group's software suite with its new CUBE-R 3D automated dimensional inspection solution. This laser scanning, all-in-one solution features Metrologic Group's advanced 3D measurement programming and inspection software packages, Silma and Metrolog X4 i-Robot, and combines efficiency and reliability of robotization in an automated industrial measuring cell.

Metrologic Group and Creaform have entered into a partnership in which Creaform integrates Metrologic Group's software suite with its new CUBE-R 3D automated dimensional inspection solution. This laser scanning, all-in-one solution features Metrologic Group's advanced 3D measurement programming and inspection software packages, Silma and Metrolog X4 i-Robot, and combines efficiency and reliability of robotization in an automated industrial measuring cell.

The CUBE-R is an off-the-shelf, fully integrated, automated 3D inspection solution designed for manufacturing companies requiring automated quality control directly on the shop floor. It optimizes the MetraSCAN 3D-R metrology scanner with the use of Metrologic Group's robot-dedicated measurement software, Metrolog X4 i-Robot. The solution thus provides a flexible plug-and-play, alternative to coordinate measuring machines and other robot-mounted, structured-light 3D scanners.

The CUBE-R extends the capabilities of the MetraSCAN 3D-R for the dimensional measurement of parts ranging from 1 m to 3 m with metrology-grade volumetric accuracy under real-life shop-floor conditions. Unlike conventional systems, the CUBE-R delivers both speed and volumetric accuracy, consequently insuring a significant increase in productivity.

Integrating Metrologic Group's Silma X4 i-Robot and Metrolog X4 i-Robot, the CUBE-R delivers an array of benefits: The software calculates the most efficient positioning of the sensor and the best collision-free trajectories for the robot. The same software manages the optical 3D measurements, simultaneously provides advanced analysis of the results –even when computing huge point clouds–, and edits personalized, easy-to-understand reports. In short, Metrolog and Silma X4 i-Robot turn the CUBE-R into a simple automated measurement solution, easily operated by a non-specialist operator.

Multi-Benefit Solution

- High productivity: Performs effective inspections on several hundred parts a day (even on dark or reflective parts with complex geometry)

- Maximizes production cycle and throughput by simultaneously operating data acquisition and delivering analysis in a continuous and uninterrupted measurement flow

- Efficient 3D measurement programming and computing: Best-in-class measurement software suite, able to manage huge point clouds

- Automatic field calibration procedure: No accuracy drift over time and continuous operation

- Minimum operator training: Easy-to-use and short learning curve to keep up with fast production pace

- Complete turnkey solution: No integration required, fully enclosed and shop-floor ready

- Small factory footprint: A complete 4.1 m x 4.1 m x 3.1 m turnkey solution with a flexible shop-floor configuration

"Metrologic Group is dedicated to developing the automated 3D metrology market through its X4 i-Robot platform," says Stéphane Auclair, division vice president, marketing and product management at Creaform-AMETEK. In addition to being recognized as world leader of dimensional metrology software, Metrologic Group is the only independent software partner to integrate robot path planning and simulation with other automation-type functionalities. Partnering with them for the commercialization of the CUBE-R was an obvious choice for us."

"The CUBE-R is yet another illustration of the ability of the Metrolog and Silma X4 i-Robot software suite to control singly the most advanced 3D measuring solutions," says Bertrand Gili, president of Metrologic Group. "Combined with the CUBE-R, our software suite brings advanced 3D inspection technology to the shop-floor and offers easy to program, easy to operate quality control routines for complex robotized inspection scenarios. It definitely sets a new standard in all-in-one laser line scanning robotized 3D inspection."