SOLO L Tooling

SOLO L Tooling

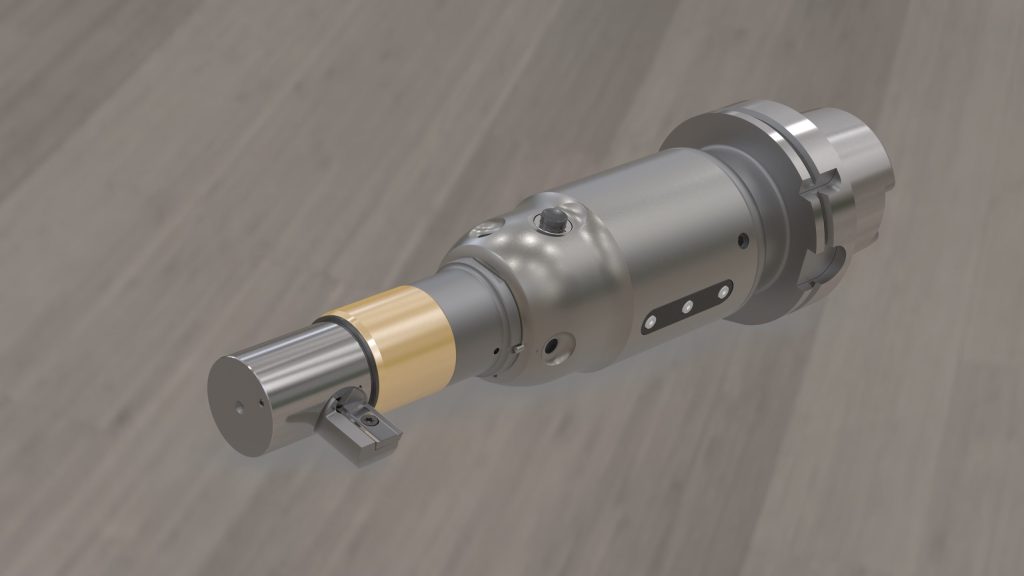

The SOLO L uses two centrifugal weights installed in a sealed tool head. With an activation speed rate of 1600 rpm or higher, the weights start moving outwards and turn the gearwheel, which drives the blade out by rotating the blade control. When the spindle is stopped and then actuated to cutting speeds, a pullback spring pushes the centrifugal weights back to the center and the blade extends to the cutting diameter. Maximum machining speed is 900 rpm.

HEULE, a world leader in tool development, introduces SOLO L tooling for spot facing and counterboring projects over 25 mm. Front and back counterbores up to 1.95 x bore diameter can be produced in bores ranging from 25.0mm – 45.0mm in diameter.

SOLO L features a simple, reliable design which functions without an anti-rotation device, change in spindle rotation, coolant pressure, or Contact mechanism. This sealed system prevents coolant contamination, and the pin-driven cutting blade, which moves in and out radially, prevents chips from jamming the system. SOLO L is completely customizable, with the tool's blade housing, blade control, and blades individually designed to meet specific project requirements. This unique system cuts interruptions and difficult materials like nickel, titanium, and other exotic alloys, making it ideal for a wide range of CNC, transfer, multi-spindle, and conventional machining applications.

The SOLO L uses two centrifugal weights installed in a sealed tool head. With an activation speed rate of 1600 rpm or higher, the weights start moving outwards and turn the gearwheel, which drives the blade out by rotating the blade control. When the spindle is stopped and then actuated to cutting speeds, a pullback spring pushes the centrifugal weights back to the center and the blade extends to the cutting diameter. Maximum machining speed is 900 rpm.

In addition to the L model, three other SOLO models are available, each is capable of counterboring two times the bore diameter minus 1mm. Possible applications up to 40mm through hole depending on the counterbore to bore ration, and parameters (max ratio is dx2-1mm). In most cases through coolant is optional, with a 280-psi maximum.

The SOLO L builds on the reputation that Heule has earned for providing strong automatic back boring tools which cut the most difficult materials and counterbore geometry. Their tools cut on center and are designed to use the maximum pilot size allowed, helping to guarantee stability even in deep hole applications, The patented Heule pin-drive system activates the cutting blade radially, which prevents chips from interfering with the tools operation. Keyed blades with no sharp corners and smooth transitions add strength to both the housing and the cutting blade.