Spray Cleaning System

Spray Cleaning System

Increasing demands on cleanliness, in terms of freedom from both particulate and film-type contaminants, call for the use of adapted cleaning solutions. These now include a new spray cleaning system for solvent-based cleaning machines by Ecoclean.

Increasing demands on cleanliness, in terms of freedom from both particulate and film-type contaminants, call for the use of adapted cleaning solutions. These now include a new spray cleaning system for solvent-based cleaning machines by Ecoclean. With this process option, spray processes and injection flood washing can be performed at adjustable pressures between 10 and 16 bar via two spraying bars. The additional cleaning capability delivers markedly improved cleaning results on geometrically complex parts and bulk-cleaned items.

Spray cleaning systems are already a feature on many solvent-based cleaning machines today. However, their spraying pressure is commonly in the range of 2 to 3 bar. With densely packed bulk items and geometrically complex workpieces exhibiting undercuts, threaded holes and blind holes – and, at times, parts obtained by additive manufacturing – that pressure will not suffice to achieve increased standards of cleanliness, i.e. an effective removal of film-type and/or particulate contaminants. This is because downstream processes such as coating, adhesive bonding and heat treatment require significantly cleaner surfaces today. Ecoclean GmbH has responded to this trend by developing a so-called high-pressure spraying system for solvent-based cleaning machines. This system allows spraying processes and injection flood washing with hydrocarbons or modified alcohols to be conducted at 10 to 16 bar pressure.

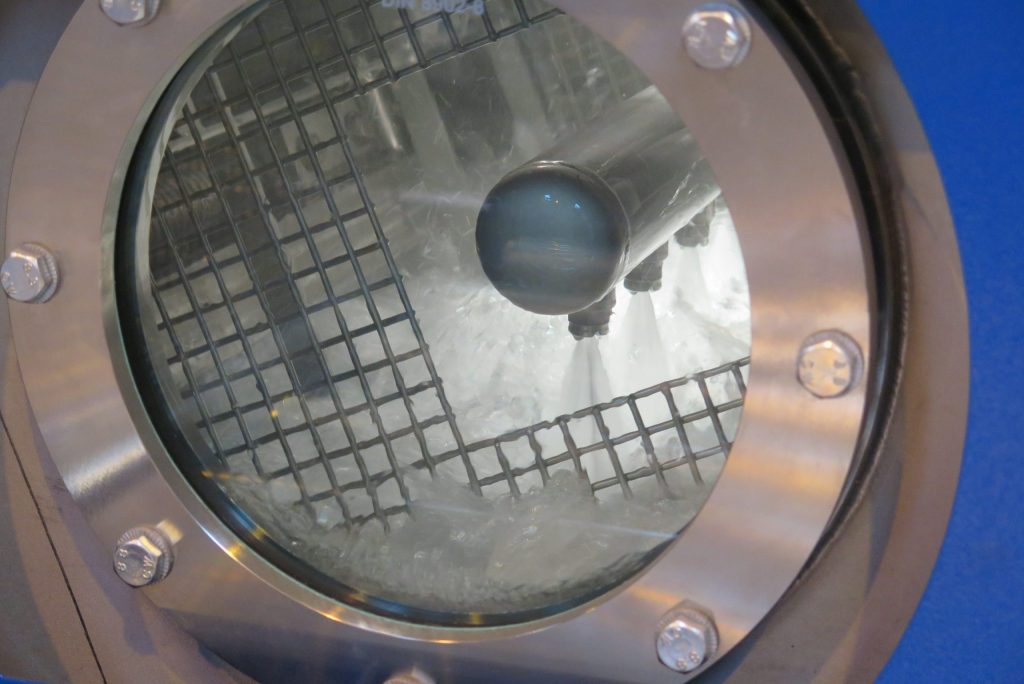

For the high-pressure spray cleaning option, the cleaning machine – e.g. an EcoCcore model – is equipped with a high-pressure pump and additional spraying bars in addition to any 2 to 3 bar spraying device that may already be fitted. One spraying bar is mounted on the interior wall of the work chamber. The second is placed centrally in the work chamber to provide both interior or exterior spraying, either simultaneously or in an alternating pattern. The spray pressure is adjusted via the high-pressure pump, which is controlled by variable-frequency drive. The number of nozzles and the product movement can be conveniently adapted to optimize the spraying process for a given part size and geometry. Moreover, this sophisticated and easy-to-handle technology supports the use of various nozzles matched to the specific application in terms of size and jet shape. As usual, the pressure, spray duration, spraying mode (simultaneous or alternating) and product movement can be defined in a part-specific cleaning program and stored in the machine controller.

Enhanced cleanliness of oriented or bulk parts For the interior and exterior spraying step, the parts – whether oriented or bulk – are positioned and secured in special carriers. With oriented parts the cleaning medium can thus be selectively directed at critical zones. Defined movements of the wash load carrier ensure that the spray jet will reach all areas. Throughout the process, contaminants become dislodged from the part surface by the spray jet's mechanical energy. At the same time, the high fluid exchange rate causes dislodged foreign matter to be flushed away from these areas so that a markedly improved cleaning result is obtained.

The high-pressure spray cleaning capability also offers advantages in cleaning densely packed bulk items. Due to the elevated pressure, an improved penetration of the packing will be achieved. Furthermore, the (high-pressure) injection flood washing cycle is performed with much more intense turbulences which, in turn, contributes to a higher cleaning quality.

For cleaning processes requiring only external spraying and/or no high pressure application, the central spray bar can be removed in a few simple steps. In this case the entire volume of the work chamber will be available to accommodate standard cleaning containers.