Straight Cutting Torches

Straight Cutting Torches

ESAB's Global Center of Excellence for Gas Apparatus introduces a new line of manual Straight Cutting Torches (SCTs) as part of its new Elite Series of gas apparatus products.

ESAB's Global Center of Excellence for Gas Apparatus introduces a new line of manual Straight Cutting Torches (SCTs) as part of its new Elite Series of gas apparatus products. The new torches provide up to 50 percent more cutting capacity than comparable designs with the ability to cut up to 10 inches when using acetylene, and up to 12 inches with alternate fuel gases.

ESAB's new Elite Series torches deliver unmatched performance and superior safety with the patented Elite Swirl Head Injector design. This revolutionary design optimally mixes high pressure preheat oxygen and lower pressure fuel gas to create a vacuum producing "entrainment zone" that pulls gas through the torch. As a result, the risk of damaging flashback is minimized. This exclusive design also creates the best mix of preheat gases achievable while doing so in the torch head, which is the furthest point from the user. Flashbacks typically occur at the point where fuel gas and oxygen mix together. ESAB's design creates this preheat mixture in the safest location possible.

In addition, the Elite Swirl Head Injector improves performance with long hoses and low-pressure operations, and provides a more thorough mixing of gases than conventional methods.

Elite SCTs have the flexibility to work with multiple fuel gas types. The Elite Series provides the only cutting torch capable of changing from a positive pressure universal mixer to a universal injector simply by changing the cutting tip from acetylene to any alternate fuel gas. This eliminates the need to change the mixer to match the fuel gas or have different cutting torches for different fuels.

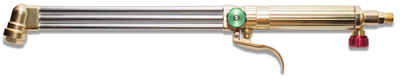

Additionally, Elite Series SCTs feature a 3-tube, in-line design that provides for increased gas flow, performance and durability. The strength of the 3-tube design permits a higher cutting capacity in acetylene and alternate fuel gases, which may eliminate the need for larger, more expensive heavy-duty cutting torches.

The torches also feature an internal tip nut which keeps the cutting tip seated, thereby reducing the risk of leaks when temperatures rise and thermal expansion takes place. This unique design also protects the threads on the head of the cutting attachment from damage when changing tips.

ESAB's latest torches are equipped with color-coded pressure adjustment knobs for quick and easy identification of gases. The cutting oxygen lever and valve are designed for "ease-on" control of cutting oxygen, which reduces the potential for blowback when piercing and increases user confidence. The torch is properly weighted for comfort and reduced operator fatigue. The new Elite Series of torches includes the Oxweld SCT-1500 family, which use Oxweld 1500 series cutting tips, and the Purox SCT-4200 family, designed for use with Purox 4200 series cutting tips.