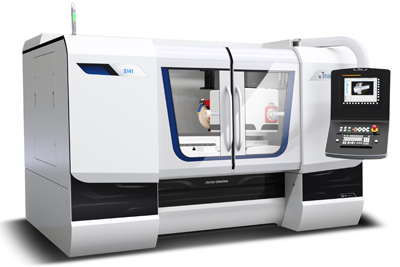

Studer S141 ID Cylindrical Grinding Machine

Studer S141 ID Cylindrical Grinding Machine

United Grinding introduced the new Studer S141 universal I.D. cylindrical grinding machine that offers the ability to internally grind longer workpieces common to the machine tool, drive element, aerospace and toolmaking industries.

United Grinding introduced the new Studer S141 universal I.D. cylindrical grinding machine that offers the ability to internally grind longer workpieces common to the machine tool, drive element, aerospace and toolmaking industries. The S141 combines both cutting edge and proven technologies with optimal ergonomics and ease of use, while delivering dependability, quality and precision, according to the company.

The S141 features two big sliding doors for optimum accessibility and is available in three different design sizes to machine workpieces with maximum lengths of 11.81" (300mm), 27.56" (700mm) and 51.18" (1,300mm) and inside diameters up to 9.84" (250mm). These grinding capacities make the S141 ideal for processing chuck components, spindle shafts, spindle housings, rotor shafts and other such parts.

The S141's grinding spindle turret accommodates up to four grinding spindles (including a maximum of two external grinding spindles), a universal measuring probe and internal grinding quills in lengths up to 10.433" (265mm). This allows both internal and external machining of workpieces in the same clamping, minimizes noncut times and boosts part accuracy. With a direct-drive integrated swivel axis and high-resolution measuring system, the turret rotates/positions quickly and precisely for a repeatability of less than one angular second.

In addition to a workhead that can be direct or belt driven, the S141's workpiece table automatically swivels from -10 to +20 degrees via the machine control for axis parallel grinding of tapers. Up to two pivoting dressing units for fixed or rotating dressing tools mount on the machine and ensure the grinding wheels stay sharp throughout the machining operations to provide maximum performance and process stability.

The S141 features a machine bed made of patented Granitan S103 mineral casting that dampens vibration and provides excellent thermal stability for superior surface quality and workpiece accuracy. The machine also incorporates the StuderGuide system for its X and Z axes. They are coated with Granitan S200 wear-restistant guideway surfacing material for the highest precision and load bearing capacity as well as strong damping across the machine's entire speed range.

With its ergonomic and user-friendly design, the S141 changes over in the shortest times possible and is easily reprogramed. The machine's 31i B series FANUC Control with integrated PC and a 15" touch screen facilitates intuitive operation. Two different operating systems, StuderWIN and StuderSIM, are available and suitable for a variety of internal grinding applications, dressing and process-supporting measurement.