SuperTurnZ

SuperTurnZ

It represents a highly productive alternative to conventional turning where 80° & 35° corner inserts are fed in the same direction, and instead utilizes all 4 directions available on conventional 2 axis lathe (+Z, -Z, +X, -X) to maximize material removal. The double-sided positive SuperTurnZ inserts have the same axial & radial rake angle and capability as standard ISO positive inserts, allowing for low cutting forces, but with double the cutting edges and much higher feed rate capabilities.

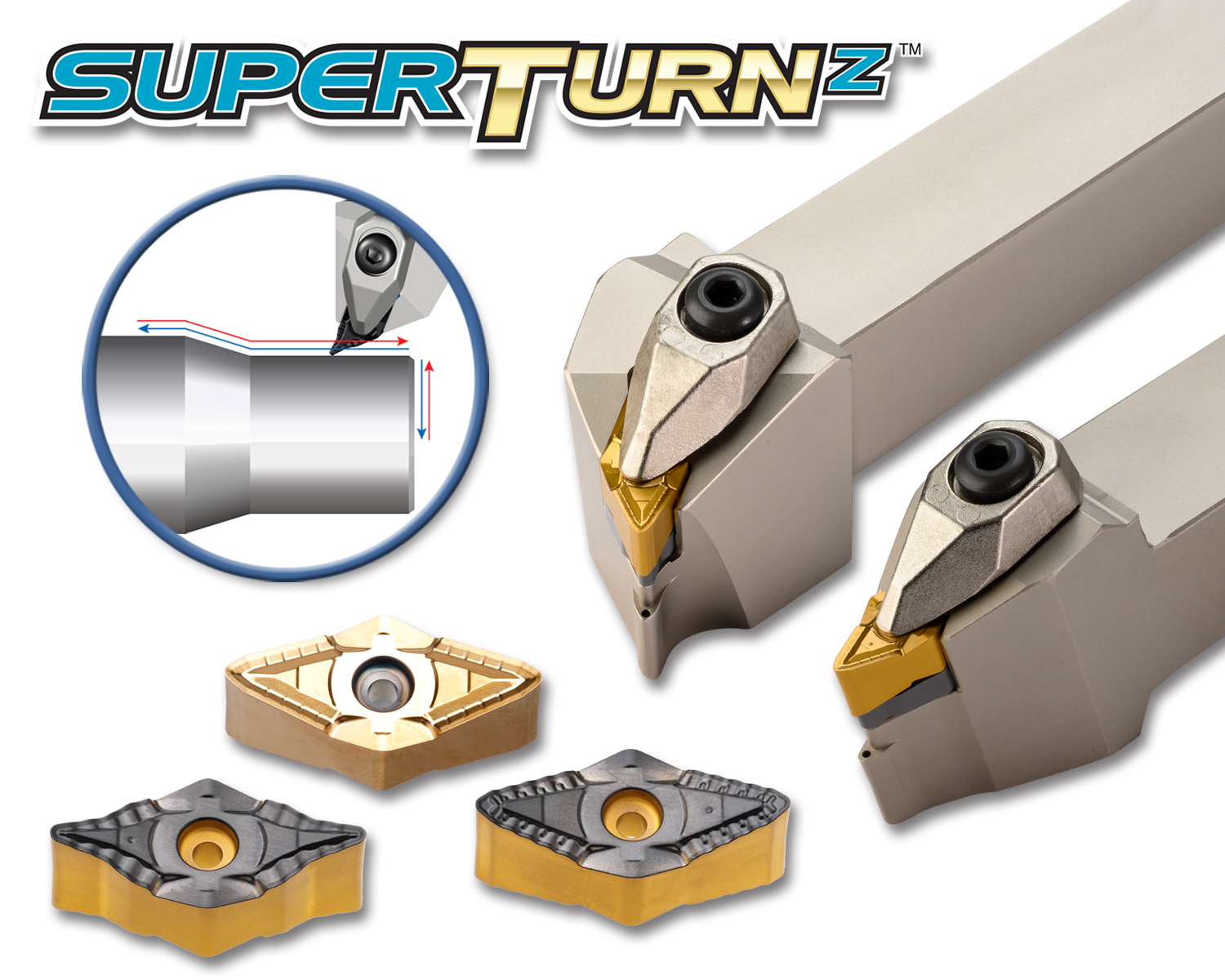

SuperTurnZ is an innovative system for multi-directional turning that utilizes the front and back cutting edge of a 4-corner insert in a single tool. It represents a highly productive alternative to conventional turning where 80° & 35° corner inserts are fed in the same direction, and instead utilizes all 4 directions available on conventional 2 axis lathe (+Z, -Z, +X, -X) to maximize material removal. The double-sided positive SuperTurnZ inserts have the same axial & radial rake angle and capability as standard ISO positive inserts, allowing for low cutting forces, but with double the cutting edges and much higher feed rate capabilities.