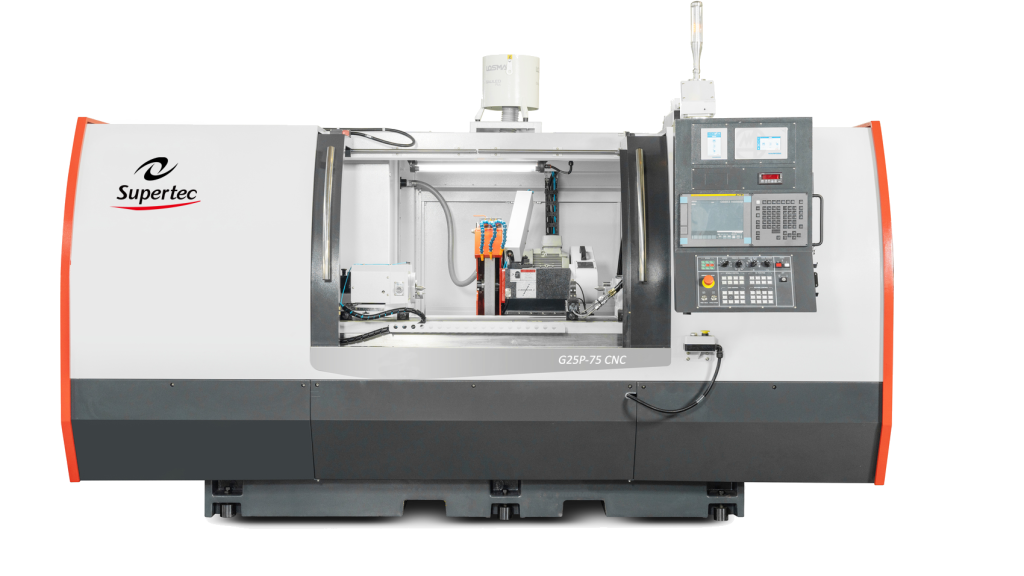

Supra Series CNC Cylindrical Grinders

Supra Series CNC Cylindrical Grinders

The Supra Series is an affordable alternative for applications of smaller diameter, long thin parts. The standard iGrind conversational software is ideal for improving programming and set-up times and is easy to learn for first time operators.

Supertec Machinery (Paramount CA) is proud to introduce the Supra series CNC Cylindrical Grinders to the North American market. With both Plunge and Anglehead designs available they offer a work envelope of 10" swing x 20", 30" or 40" between centers.

The Supra Series is an affordable alternative for applications of smaller diameter, long thin parts. The standard iGrind conversational software is ideal for improving programming and set-up times and is easy to learn for first time operators.

The iGrind conversational software is offered on both Mitsubishi and FANUC controls. An optional Babbit bearing wheelhead spindle allows for easy grinding and maximum finishes of hard materials such as carbide or ceramics. The table is fully supported on both ends for Improved accuracy and repeatability.