Surface Measure 1008S

Surface Measure 1008S

The Surface Measure 1008S aims to disrupt the surface measurement processes across a wide range of industries, offering unprecedented precision and accuracy, even with in-line and near-line shop floor applications. The SM1008S leverages a propriety Mitutoyo optical system alongside our traditional sensor technology to deliver versatile performance that includes 2D profile measurements and comprehensive 3D dimensional inspections.n

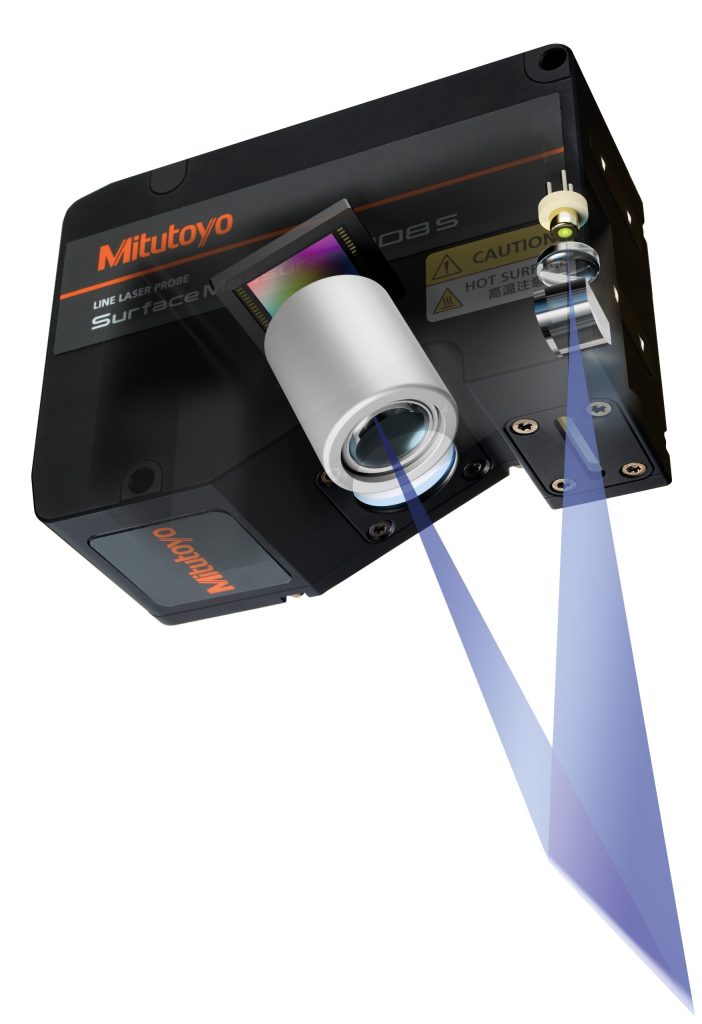

Mitutoyo America Corporation, a leading manufacturer of precision metrology instruments and solutions, is proud to announce the release of our innovative SM1008S, the first non-contact line-laser sensor in the Mitutoyo Surface Measure product line.

The Surface Measure 1008S aims to disrupt the surface measurement processes across a wide range of industries, offering unprecedented precision and accuracy, even with in-line and near-line shop floor applications. The SM1008S leverages a propriety Mitutoyo optical system alongside our traditional sensor technology to deliver versatile performance that includes 2D profile measurements and comprehensive 3D dimensional inspections.

Key Features and Benefits:

- Exceptional Precision and Repeatability: The SM1008S boasts an accuracy of 20 µm and a Z repeatability of 0.5 µm, ensuring reliable and consistent measurements. This precision allows for stable inspection and measurement of intricate details and complex surfaces.

- Integrated Smart Software: The sensor's on-board software includes a wide array of measurement tools such as height, width, volume, flatness, pattern matching, gap & flush, optical character recognition (OCR), barcode reading, and various defect detection tools. These features eliminate the need for additional controllers or complex programming, simplifying setup and operation.

- Robust and Versatile Design: Designed to withstand demanding environments, the SM1008S achieves an IP67 protection level. It supports automated measurements with high-speed profile acquisition (up to 10 kHz) and features a parts matching function for consistent application regardless of part orientation.

- Wide Range of Applications: Suitable for industries including electrical, electronics, semiconductor, automotive, food, medical device, and pharmaceuticals, the SM1008S facilitates 100% in-line inspection, enhancing quality control and productivity.