Contact Details

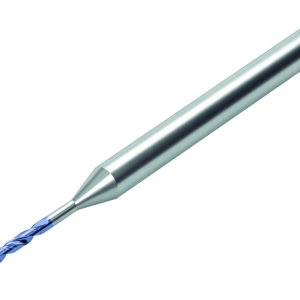

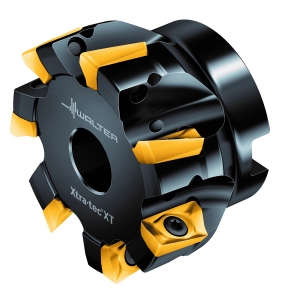

Walter has introduced the T2713, a universal indexable thread mill suitable for a variety of materials up to 55 HRC. This newest addition to the Walter thread milling system combines the advantages of thread milling with the efficiency of tapping. Due to the smooth cutting and lower cutting forces, machining times can be comparable to those of thread tapping and forming.

In addition to fast machining, users also benefit from the high process reliability of thread milling, ease of handling and few radius corrections, high operational smoothness, cylindrical threads, and excellent thread quality. The new, flexible T2713 handles various thread pitches and lengths and features a modular tool body with Walter Capto C8 interface for large threads and/or long overhangs.

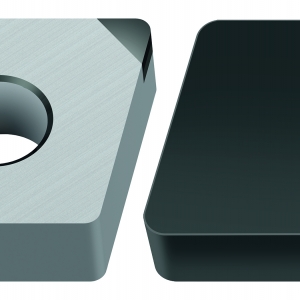

In conjunction with its release of the T2713 Walter is also releasing its 22 mm IC, P26300 thread milling insert. This new insert is ideal for machining thread diameters starting at M125 with a thread pitch between 6 to 10 mm, or UN5 in. with a thread pitch of 4 tpi. The insert, with 55° flank angle, is designed for use in single row bodies and has D61 geometry for maximum process reliability.

Related Glossary Terms

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- inscribed circle ( IC)

inscribed circle ( IC)

Imaginary circle that touches all sides of an insert. Used to establish size. Measurements are in fractions of an inch and describe the diameter of the circle.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- pitch

pitch

1. On a saw blade, the number of teeth per inch. 2. In threading, the number of threads per inch.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.

PRODUCTS

PRODUCTS