Contact Details

Walter has introduced the TC388 and TC389 Supreme solid carbide taps, for solving key problems in threading hardened steel, in part because producing threads in hardened steel has traditionally been both costly and time consuming. This especially applies to blind hole machining in particular…because reversing the tap during this process can cause torque peaks when the root of the chip is sheared off, resulting in tool failures.

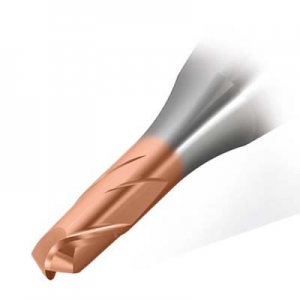

Walter solves this problem with the TC388 Supreme (50–58 RC) and TC389 Supreme (55–65 RC) with their new patent-pending cutting geometries that fully shear off the root of the chip when reversing, thus torque peaks are minimized. This prevents fractures, prolongs the tool life, and increases process reliability. Furthermore, the new taps are coated using Walters new HiPMS coating technology which creates a better surface finish, and higher thread form quality due to this innovative new coating process. Lubrication with oil, which was often necessary until now, is no longer required. Instead, standard water-based emulsions can be used, optimizing handling and saving additional machining costs. The TC388 and TC389 can be used for tapping both blind-hole and through-hole threads up to 2 × DN.

The Walter lineup of products consists of three categories to tools. Supreme tools indicate the highest level of technology and performance available. Advance tools indicate product efficiently balanced between price and performance and Perform tools are products that provide an economical solution with focused importance on price.

Related Glossary Terms

- blind-hole

blind-hole

Hole or cavity cut in a solid shape that does not connect with other holes or exit through the workpiece.

- tap

tap

Cylindrical tool that cuts internal threads and has flutes to remove chips and carry tapping fluid to the point of cut. Normally used on a drill press or tapping machine but also may be operated manually. See tapping.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

- through-hole

through-hole

Hole or cavity cut in a solid shape that connects with other holes or extends all the way through the workpiece.

PRODUCTS

PRODUCTS